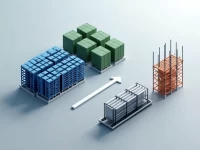

Warehouse Racking Systems Boost Logistics Efficiency

This paper explores the role of diverse racking systems in improving warehouse efficiency. It analyzes the limitations of traditional selective racks and introduces various racking solutions, including drive-in, shuttle, mobile, cantilever, and mezzanine racks. The paper emphasizes key factors to consider when selecting racking, such as cargo characteristics, warehouse layout, operating model, budget, and safety factors. The aim is to assist businesses in optimizing warehouse space and enhancing operational efficiency.