Imagine an expensive precision instrument enduring violent turbulence and unpredictable temperature fluctuations at 30,000 feet, only to arrive damaged due to inadequate packaging. Such scenarios deliver a dual blow to both corporate profits and brand reputation. International air transport, particularly express air freight, imposes stringent packaging requirements. The challenge for exporters lies in striking the optimal balance between high protection and low costs.

This analysis examines critical strategies for shock and moisture protection in international air freight, offering enterprises practical solutions to reduce cargo damage rates while optimizing logistics expenditures.

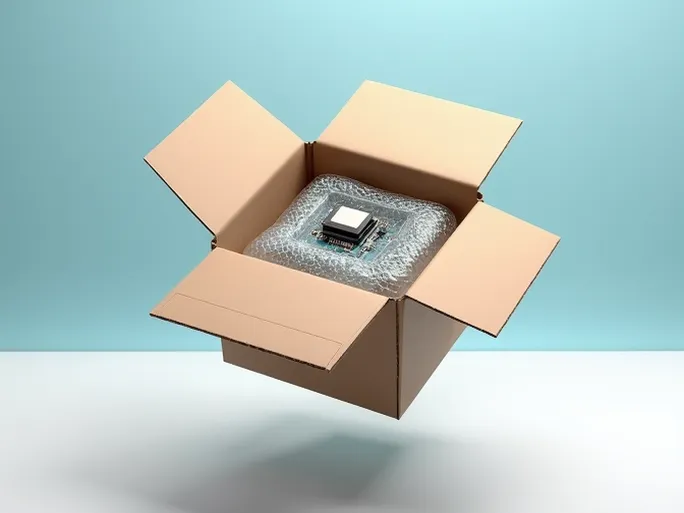

Shock Absorption Packaging: Layered Cushioning to Dissipate Impact

During air transport, cargo faces both vertical impacts and continuous vibrations. Effective shock protection requires gradient cushioning structures that progressively dissipate kinetic energy.

- Inner Layer: Contoured Protection. Closed-cell EPE foam padding is recommended for its independent bubble structure that conforms precisely to product contours, effectively distributing instantaneous impacts. Irregularly shaped items benefit from custom-molded EPE cushions.

- Middle Layer: Vibration Dampening. Honeycomb cardboard or polypropylene foam sheets should overlay the inner layer. The corrugated structure of honeycomb board absorbs high-frequency vibrations through deformation, while polypropylene foam provides elastic recovery for repeated impacts.

- Outer Shell: Structural Reinforcement. Five-ply reinforced corrugated boxes or wooden crates exceeding 18mm thickness create rigid external protection. Metal edge protectors on box corners enhance collision resistance.

- Fragile Items: Targeted Reinforcement. Glass products require L-shaped corner protectors, while electronics demand anti-static bags to prevent circuit damage from friction-induced charges.

Dimensional constraints must also be considered—individual packages should maintain longest dimensions under 114cm to avoid special handling fees.

Moisture Barrier Systems: Sealed Enclosures with Active Monitoring

High-altitude low-pressure environments accelerate moisture penetration. Effective humidity control combines physical barriers with real-time monitoring.

- Humidity Tracking: Montmorillonite desiccants paired with humidity indicator cards provide active moisture absorption and visual alerts when relative humidity exceeds 60%.

- Physical Barriers: Waterproof polyethylene film creates complete moisture seals, supplemented by tape-sealed container ventilation holes.

- Liquid Cargo: Containers must include 5-10% expansion space with leak-proof membrane wrapping and absorbent inner liners.

- Electronics: Anti-static coatings provide additional protection against humidity-induced short circuits.

Comparative analysis of carrier-specific packaging surcharges through freight platforms can prevent cost overruns.

Cost-Protection Optimization

Effective air freight packaging prioritizes strategic material selection over excessive protection. Route-specific adjustments—like reducing desiccants on arid routes—can yield significant savings while maintaining protection standards.

Integrated shock absorption and moisture barrier systems demonstrate remarkable efficacy, with industry data showing over 90% reduction in cargo damage when properly implemented.

Customized Solutions

Given frequent fluctuations in air freight packaging costs, consultation with specialized logistics advisors is recommended. These professionals develop tailored solutions accounting for product specifications, route conditions, and destination regulations.

Implementation Note: These recommendations align with International Air Transport Association (IATA) standards and industry best practices. Actual application requires verification against current airline policies and destination country regulations.