In today's rapidly globalizing economy, international trade and cargo transportation have become vital pillars of national economies. The explosive growth of e-commerce and cross-border transactions has made container shipping—an efficient and convenient transportation method—increasingly important. However, the safe transport of containers remains a significant concern, particularly during road transportation. This is where chassis play an indispensable role.

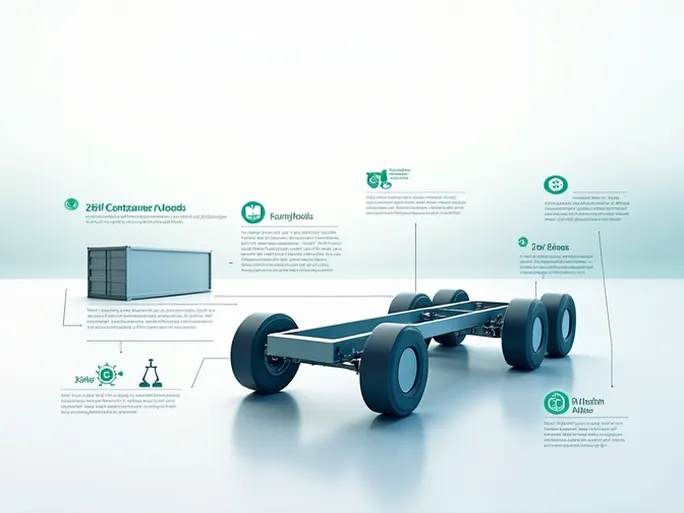

A chassis is a specially designed trailer or undercarriage that provides road transportation support for shipping containers. Its precise compatibility with containers ensures stability and safety during transit. Whether for bulk cargo or full container loads, chassis are essential components of the transportation process. Particular attention must be paid to chassis fees, which constitute an integral part of transportation services. For overweight container cargo, chassis design becomes especially crucial—particularly when using tri-axle chassis.

The Importance of Tri-Axle Chassis

Tri-axle chassis feature three wheel axles designed to distribute weight and enhance stability. When container cargo exceeds certain weight thresholds, these specialized chassis become necessary. For 20-foot containers, tri-axle chassis are required when cargo weight surpasses 36,000 pounds. Similarly, for 40-foot containers exceeding 44,000 pounds, tri-axle configurations must be employed.

This engineering ensures containers remain securely fastened during transit. Container movement and displacement constitute primary causes of cargo damage, and proper chassis selection significantly reduces these risks. Choosing the correct chassis not only safeguards cargo but also improves transportation efficiency while minimizing potential economic losses.

Market Diversity and Technological Advancements

The market offers various chassis specifications, including 20-foot and 40-foot models, accommodating diverse container sizes and transportation needs. Modern chassis designs increasingly emphasize both convenience and safety, with improvements in shock absorption and anti-slip features that maintain stability across challenging road conditions.

Precision engineering ensures perfect compatibility between chassis and containers regarding dimensions and structure. These advancements reduce overall weight while maintaining cargo and equipment safety, providing reliable stability even during long-haul transportation and consequently improving overall efficiency.

Cost Considerations and Technological Integration

Chassis fees represent a significant factor in corporate cost calculations. These expenses, typically calculated based on transportation distance, cargo weight, and other variables, can be optimized by partnering with reputable transportation providers that ensure both safety and punctuality.

Technological progress has enabled logistics companies to implement internet-based chassis management systems. Modern tracking solutions allow real-time monitoring of chassis status and location, dramatically improving transportation transparency and efficiency. Predictive analytics can identify potential issues before they occur, enabling proactive measures to guarantee smooth cargo delivery.

In conclusion, chassis play a pivotal role in container transportation—from ensuring cargo safety to optimizing operational efficiency. Regardless of complexity, proper chassis selection remains fundamental to successful container delivery. In our increasingly busy transportation industry, professional teams stand ready to provide reliable solutions that ensure secure container shipping and business growth. Through continuous service improvement, we aim to become the most trusted partner in cargo transportation.