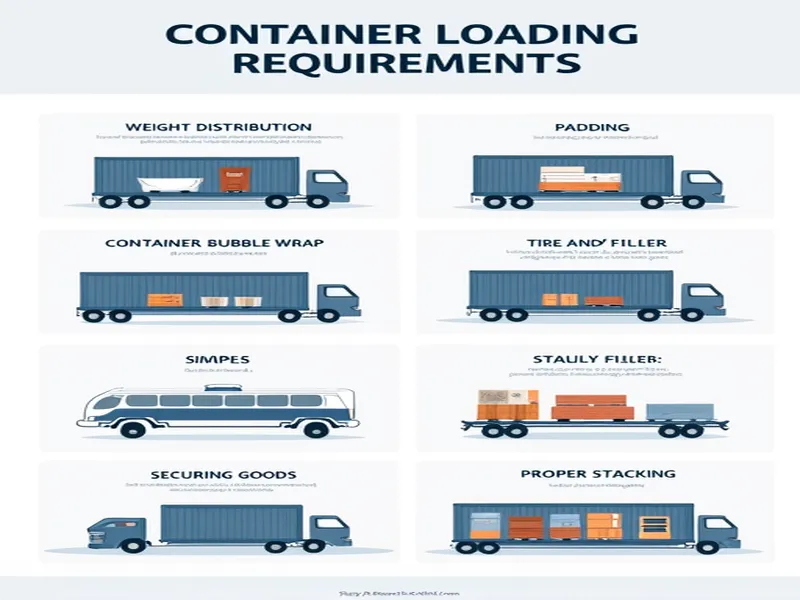

In container transportation, ensuring that goods reach their destination smoothly and safely is the primary goal of every shipping company. Achieving this requires strict adherence to loading requirements. This article explores four critical aspects of container loading: proper weight distribution, necessary padding, cargo securing, and appropriate mixed loading.

1. Proper Weight Distribution

The importance of proper weight distribution during loading cannot be overstated. Cargo must be classified by volume, weight, packaging strength, and characteristics to make informed loading decisions. A fundamental principle is placing heavy, sturdy items at the container's bottom to create even weight distribution, preventing floor detachment or bottom rail bending. Proper weight distribution also enhances transport stability and reduces tipping risks.

2. Essential Padding

When transporting fragile or weakly packaged goods, proper padding is crucial. Buffer materials like foam, cardboard, or plastic bags fill gaps between items and container walls, reducing collision damage during transit. This protective measure maintains cargo integrity and minimizes potential losses from accidents.

3. Cargo Securing

Proper securing is the third critical loading component. Unsecured cargo can shift, topple, or break during transit, jeopardizing the entire shipment. Support, bracing, and restraint measures—using straps, locks, or filler materials—ensure stability throughout transport. Whether for long-haul or short-distance shipping, securing every item is essential to minimize vibration damage.

4. Appropriate Mixed Loading

Mixed loading requires careful consideration to avoid contamination or hazardous combinations. Separate wet from dry goods, strongly scented items from sensitive products, and differently packaged cargo. Proper mixed loading prevents quality issues from contact and ensures transport safety, avoiding potentially significant losses.

Following these four loading principles reduces cargo damage rates and enables safer shipping. Proper warehousing and transport protect goods while maintaining client trust. Understanding and implementing these requirements improves efficiency and service quality—all logistics professionals should master these fundamentals.

Additionally, comprehensive knowledge of container types (refrigerated, open-top, flat rack, etc.), sizes, and suitable cargo categories enables flexible problem-solving during operations. Environmental considerations matter too—select sustainable packaging materials and methods to minimize ecological impact.

Container loading is a specialized, collaborative process. Mastering loading requirements significantly enhances safety and efficiency, ensuring timely, secure deliveries. All personnel must remain vigilant, continuously improving their expertise to guarantee smooth operations. Prioritizing safety and efficiency delivers superior service to clients.