In air cargo logistics, Unit Load Devices (ULDs) serve as the crucial bridge between freight and aircraft compartments, with their importance being paramount. The types of ULDs and their loading restrictions directly impact both transportation efficiency and flight safety. Given the diversity of cargo types and aircraft models, how can logistics professionals effectively select the appropriate ULD? This complex yet critical subject warrants thorough examination.

ULD Types and Design Specifications

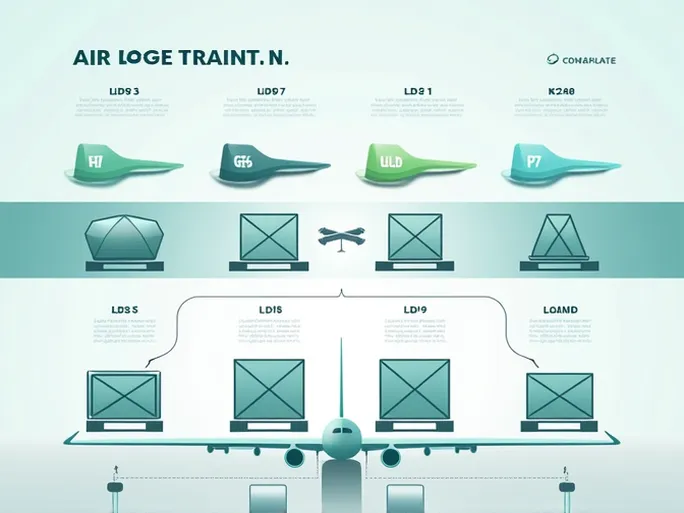

ULDs primarily consist of two forms: containers and pallets. Containers are meticulously designed to accommodate the physical boundaries of aircraft compartments. For instance, the LD3 container is specifically engineered for wide-body aircraft lower decks, featuring a sloped top structure that conforms to the curvature of the cabin. With a standard volume of 4.3 cubic meters and a height restriction of 163 centimeters, it maximizes space utilization.

Pallets, conversely, utilize nets to secure cargo and adapt to the irregular spaces of main decks. The P6 pallet, measuring 318 cm × 244 cm, permits cargo overhang, thereby expanding loading width capacity.

Identification Codes and Compatibility Considerations

The 10-digit identification code plays a vital role in ULD selection. The first letter indicates type—"A" for certified containers and "P" for pallets—while subsequent letters define base dimensions, and the final two digits identify the owning airline, creating a global tracking system.

Improper selection can lead to compartment incompatibility. For example, the B767's cabin width limitations prevent accommodation of dual LD3 containers, necessitating use of narrower LD2 units. Similarly, employing P7E pallets beyond their intended 747 aircraft may result in door clearance issues.

Loading Constraints and Operational Parameters

Loading operations must observe multiple restrictions regarding weight, space, and mechanical stability:

- Weight limitations: LD3 containers have a 1,588 kg maximum, while AMA containers can support 6,800 kg. Exceeding these limits affects aircraft weight distribution.

- Load distribution: Palletized cargo requires even weight dispersion, with single-point pressure not exceeding 976 kg per square meter to prevent floor damage.

- Spatial constraints: Cargo dimensions must conform to door and hold profiles. The B747's main door height (305 cm) contrasts with its 244 cm vaulted ceiling, requiring careful stacking to maintain net tension.

- Irregular cargo: Aircraft-specific contours demand special consideration, such as the 17-degree slope in A330 lower deck LD3 zones requiring angled clearance for rectangular containers.

Mechanical Stability Principles

Load planning follows fundamental mechanical principles:

- Heavy items positioned near the pallet center

- Lighter goods placed peripherally

- Minimum 20 cm clearance from edges for metal equipment

- Precision instruments requiring shock-absorbing padding for turbulence protection

Effective ULD selection and loading strategies represent a systematic matching process that balances spatial compatibility, weight equilibrium, and mechanical stability while dynamically adapting to aircraft specifications and cargo characteristics.

Industry standards referenced include International Air Transport Association (IATA) guidelines and ISO 21100:2020 technical specifications, though individual carrier manuals should always be consulted for operational implementation.