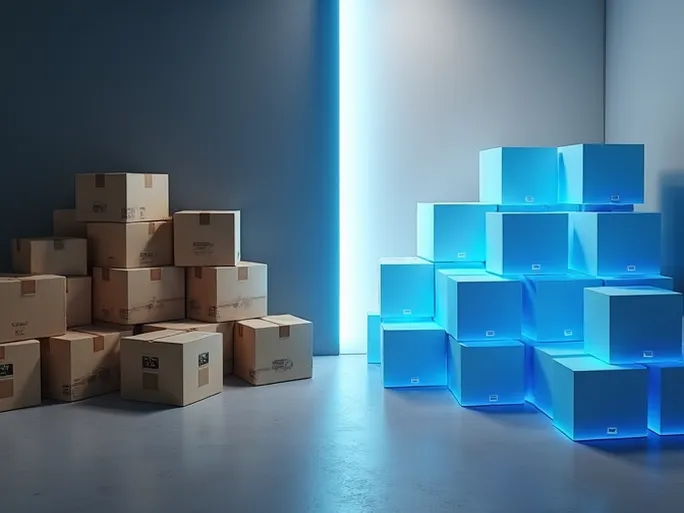

Imagine this scenario: A warehouse operations manager starts each day not with predictable routines and stable demand, but with fluctuating order volumes, an unpredictable labor market, and supply chain disruptions that appear and disappear like ghosts. This volatility represents the current reality of warehouse and distribution center operations. How can businesses remain competitive—or even excel—in this "new normal"? The answer lies in agility: a data-driven ability to quickly adapt to changes and seize opportunities.

This report, "Navigating Uncertainty: How Warehouse Leaders Win With Agility," analyzes insights from over 120 senior supply chain executives on how they address these challenges, distilling actionable best practices. The findings are based on a presentation by Dan Keto, President and CTO of Easy Metrics, exploring how to maintain agility while ensuring operational accountability, effectively controlling labor costs under pressure, and sustaining stable performance in unpredictable environments.

Agility vs. Accountability: The Balancing Act

In pursuing agility, companies often face a dilemma: prioritize rapid response or maintain operational stability and control? Leading warehouse operations are finding balance through these approaches:

- Clear performance metrics: Identify which indicators are crucial for business success and implement real-time monitoring systems that track both outcomes and processes, enabling quick corrective actions.

- Employee empowerment: With clear metrics in place, grant staff greater autonomy to make rapid decisions based on real-time conditions, supported by trust-building cultures and proper training.

- Continuous improvement: Agility isn't achieved overnight but through ongoing refinement—collecting feedback, analyzing data, and adjusting strategies as needed.

Labor Cost Control: Surviving Under Pressure

With labor representing one of the largest warehouse expenses, effective cost management becomes critical amid worker shortages and rising wages. Top performers are implementing these strategies:

- Precision workforce forecasting: Use historical data and market trends to predict labor needs, optimizing hiring and scheduling to avoid over- or under-staffing.

- Workflow optimization: Enhance employee efficiency through automation, standardization, and lean methodologies.

- Improved retention: Reduce costly turnover by offering competitive compensation, career development, and positive work environments.

Key Performance Indicators: The 2025 Focus

The report highlights these KPIs as increasingly critical by 2025:

- Workforce forecast accuracy: The foundation for agile operations, requiring continuous refinement.

- Cycle time: Total time to complete tasks—shorter cycles boost efficiency and customer satisfaction.

- Indirect and missing time: Minimize non-productive hours (breaks, training) and absenteeism to maximize labor utilization.

- Labor standards: Scientifically established benchmarks for task completion that enable performance evaluation and improvement planning.

Data-Driven Agility: Action, Prediction, and Stability

Leading warehouses leverage data-driven agility to:

- Act faster: Real-time monitoring enables immediate issue identification and correction.

- Anticipate problems: Analyze trends to predict challenges and prepare solutions proactively.

- Maintain performance under pressure: Robust systems ensure stability despite external disruptions, enhancing competitiveness.

In today's uncertain landscape, agility separates successful warehouse operations from the rest. By balancing responsiveness with accountability, controlling labor costs effectively, and focusing on critical KPIs, businesses can transform volatility into advantage. By 2025, data-driven agility will become standard—and those who harness it best will lead the industry.