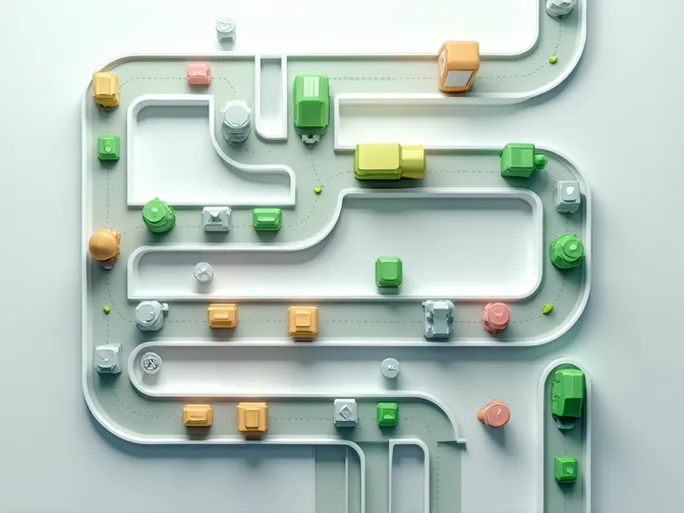

Imagine your packages navigating through a maze like laboratory mice, encountering delays and obstacles at every turn before potentially being lost entirely. The financial and reputational costs of such logistical failures can be devastating. In today's competitive marketplace, efficient logistics operations serve as a critical differentiator, and visual flowcharts emerge as powerful tools for optimizing supply chain performance.

1. Visualizing Logistics: The Foundation of Operational Efficiency

1.1 Core Components of Logistics Operations

Logistics represents the physical movement of goods or services, with the fundamental objective of delivering products from origin to destination efficiently, securely, and on schedule. This complex process involves multiple interdependent stages:

- Packaging and Labeling: The starting point that ensures product safety during transit while providing essential identification information.

- Inventory Management: Maintaining optimal stock levels to fulfill orders promptly without excessive surplus.

- Order Processing: The critical function of accurately and rapidly handling customer orders.

- Transportation: Selecting appropriate shipping methods (road, sea, or air) while optimizing routes to minimize costs.

- Warehousing: Strategic organization of storage facilities to maximize space utilization.

- Last-Mile Delivery: The final distribution stage that ensures customer receipt.

- Reverse Logistics: Managing returns and repairs to maintain customer satisfaction.

Each component represents a potential bottleneck that could compromise overall efficiency, making comprehensive process analysis essential.

1.2 Flowcharts: The Diagnostic Lens for Supply Chain Management

Flowcharts serve as indispensable visualization tools that decompose intricate logistics processes into clear, comprehensible sequences. These diagrams enable organizations to:

- Present complex workflows through intuitive graphical representations.

- Identify critical bottlenecks such as slow order processing or inefficient warehouse picking.

- Redesign processes by eliminating redundant steps or optimizing transportation networks.

- Enhance cross-departmental communication and collaboration.

- Facilitate continuous improvement through regular review cycles.

Beyond mere operational tools, well-designed flowcharts represent strategic assets that provide organizational insights for data-driven decision making.

2. Constructing Effective Flowcharts: From Theory to Implementation

2.1 Process Decomposition: Breaking Down Logistics Components

Effective flowchart creation begins with granular analysis of each logistics stage. A standard workflow might include:

- Order receipt and system entry

- Inventory verification

- Warehouse picking

- Product packaging

- Shipping label application

- Weight measurement for freight calculation

- Carrier selection based on cost and delivery timelines

- Handoff to logistics providers

- Transportation execution

- Customs clearance (for international shipments)

- Final delivery

- Recipient confirmation

- Returns processing

Organizations must customize these sequences according to their specific operational requirements and industry characteristics.

2.2 Standardized Notation: The Visual Language of Flowcharts

Professional flowcharts employ universal symbols to represent different process elements:

- Ovals: Denote start/end points

- Rectangles: Indicate process steps

- Diamonds: Show decision points with conditional branches

- Parallelograms: Represent data inputs/outputs

- Arrows: Illustrate process directionality

- Circles: Serve as connection points

- Document symbols: Indicate report generation

- Database symbols: Show data access points

Specialized diagramming software typically provides extensive symbol libraries with automatic layout features.

2.3 Structural Principles: Balancing Logic and Clarity

Effective flowchart architecture follows several key principles:

- Standard top-to-bottom, left-to-right reading orientation

- Clear emphasis on primary process flows

- Distinct branching paths at decision nodes

- Minimized line crossings to reduce visual clutter

- Modular design for complex processes

- Strategic annotation of critical steps

2.4 Optimization Techniques: The Pursuit of Perfection

Flowchart refinement represents an iterative process incorporating:

- Step simplification through elimination of non-value-added activities

- Parallel processing opportunities

- Automation integration (e.g., automated picking systems)

- Standard operating procedure development

- Continuous performance monitoring

- Stakeholder feedback incorporation

3. Practical Applications: Realizing Operational Value

3.1 Bottleneck Identification

Flowcharts enable precise localization of process inefficiencies, whether in manual data entry errors or system latency issues.

3.2 Efficiency Enhancements

Visual analysis supports targeted interventions like warehouse layout optimization or robotic picking system implementation.

3.3 Risk Mitigation

Potential supply chain vulnerabilities become visually apparent, enabling preventive measures such as transport insurance or backup routing.

3.4 Cost Reduction

Flowchart analysis reveals cost-saving opportunities through route optimization or inventory reduction strategies.

4. Tool Selection: Enabling Effective Implementation

Common flowcharting solutions include:

- Microsoft Visio (comprehensive enterprise tool)

- Lucidchart (collaborative online platform)

- Draw.io (free open-source alternative)

- ProcessOn (Chinese-developed solution with template support)

Selection criteria should evaluate functionality, usability, cost structure, and compatibility.

5. Conclusion: Visualizing Success in Supply Chain Management

Logistics flowcharts transform abstract processes into concrete visual models, enabling organizations to diagnose inefficiencies, implement targeted improvements, and maintain competitive advantage. When properly constructed and consistently maintained, these diagrams serve as living documents that evolve alongside business needs, ultimately driving measurable gains in operational performance and customer satisfaction.