In today's hyper-competitive market environment, businesses face numerous challenges alongside significant opportunities. This dynamic landscape isn't just driven by rapid technological advancement, but also by constantly evolving consumer demands and expectations. In this context, developing supply chain and logistics models that reflect a company's unique characteristics while remaining adaptable to market changes has become an imperative challenge for every organization.

However, many enterprises encounter obstacles when attempting transformation, often constrained by limited thinking patterns and rigid operational models. The lack of a systematic logical framework frequently becomes the stumbling block to their rapid development. To address this challenge, we've developed an innovative PPCO model based on extensive research and analysis of numerous corporate case studies.

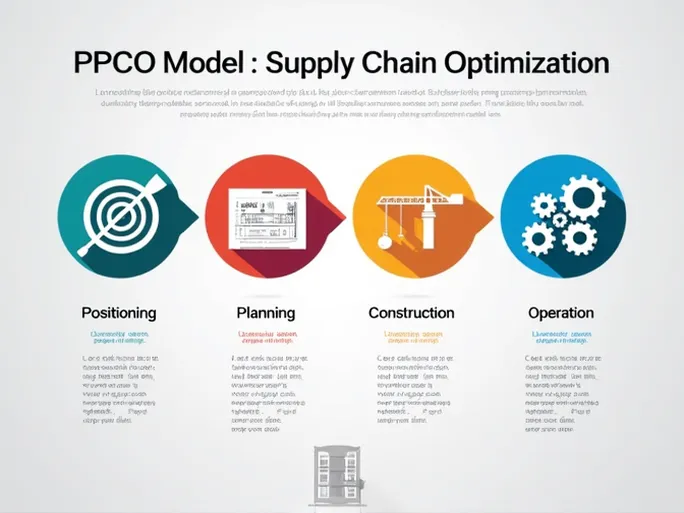

The PPCO model—standing for Positioning , Planning , Construction , and Operation —provides a clear, simple yet effective framework to guide logistics enterprises through their transformation journey. Whether for large state-owned enterprises or small-to-medium logistics companies, this model helps identify supply chain transformation objectives and pathways to achieve comprehensive business upgrades.

Step 1: Positioning - Defining Core Competitive Advantages

The first step in corporate transformation requires clearly defining core competitive advantages. The importance of this phase cannot be overstated—companies must carefully consider and determine their market entry points. Positioning not only relates to corporate vision and strategic direction but also determines a company's differentiation within its industry.

Businesses need to find the optimal balance between customer experience, cost efficiency, and operational effectiveness to maintain stability in competitive markets. Customer experience encompasses critical elements like product quality, service levels, and price competitiveness. Companies must decide whether to compete on lowest price, superior service quality, or exceptional product performance—a decision that will profoundly impact subsequent planning and construction phases.

Simultaneously, while pursuing excellent customer experience, companies must maintain internal cost control and efficiency improvements. Typically, businesses aim to excel in two of these three elements while maintaining parity in the third—for instance, ensuring service quality while controlling costs and delivery times.

To ensure goal clarity, organizations should establish a set of clear, quantifiable Key Performance Indicators (KPIs). Metrics like 24-hour delivery rates, successful delivery ratios, and various cost ratios form the foundation for subsequent phases. Only with well-defined objectives can companies deliver services that meet customer expectations and potentially gain competitive advantages.

Step 2: Planning - Developing Implementation Pathways

With clear positioning established, the next phase involves planning how to achieve the defined KPIs. This stage requires comprehensive analysis across multiple dimensions including logistics network design, organizational capability building, process and system optimization, and intelligent equipment planning.

To ensure planning rationality and feasibility, companies can employ modeling simulations for systematic analysis, allowing for timely feedback and adjustments. For example, if a company positions itself to provide auto parts to regional repair shops with a core promise of two-hour delivery, the planning process must thoroughly examine whether this target is achievable. Should planning reveal the delivery promise unattainable, the company should immediately revisit its positioning strategy—a crucial step to avoid pursuing unrealistic objectives.

Key planning considerations include regional warehouse locations, SKU assortment and inventory levels, delivery channels and timing. Through scientific and rational planning, business objectives gradually align with operational reality, helping companies reduce unnecessary waste and improve overall efficiency during continuous operations.

Step 3: Construction - Synchronizing Investment and Implementation

The construction phase represents the most resource-intensive and challenging component of the PPCO model. During this stage, companies must implement rigorous project management while maintaining constant communication between planning and construction teams to ensure information sharing and coordination, guaranteeing projects are completed on time, to specification, and within budget.

To facilitate smooth project execution, companies typically establish a dedicated Project Management Office (PMO) to oversee progress and pace. This approach helps minimize risks of ineffective investment while ensuring organic relationships between investment, schedule, and outcomes—thereby enhancing organizational execution and adaptability.

Given that construction cycles often exceed one year, companies must allocate sufficient time and resources to implement all necessary work. From high-level facility and equipment procurement to team capability enhancement, each element requires meticulous management and rigorous execution to ensure continuous feedback and adjustment throughout the construction period.

Step 4: Operation - The Cycle of Validation and Adjustment

The operational phase represents the most critical component of the PPCO model. During this stage, companies must simultaneously conduct construction and operational activities, using daily operational results to validate the correctness and effectiveness of earlier positioning decisions. This process requires re-evaluating all KPIs to ensure business objectives are being met.

During actual operations, companies should regularly conduct in-depth analysis of personnel, equipment, materials, methods, and environmental factors. When significant gaps emerge between targets and actual performance, immediate corrective actions become necessary. Establishing periodic evaluation mechanisms—such as quarterly positioning reviews—enables flexible strategy adjustments to ensure effective execution.

This phase serves as a vital measure for maintaining business stability in dynamic environments. Companies should remain vigilant during operations, always prepared to respond to market changes.

Conclusion

The PPCO model provides companies with a clear and effective logical framework for transformation, particularly suited to logistics businesses undergoing upgrades and repositioning. Whether for small-to-medium enterprises or large corporations, clearly defining core competitive advantages and following the model's four phases can help revitalize businesses while effectively enhancing competitive advantages and market share.

In future markets, only those companies capable of rapid adaptation and flexible strategy adjustments will maintain competitive edges. Through implementation of the PPCO model, businesses can identify optimal market positions, seize developmental initiative, consistently deliver superior customer service, and drive sustainable business growth.