In contemporary logistics management, warehouses play an increasingly vital role. Yet many enterprises frequently overlook the crucial process of warehouse inspections, allowing potential risks and efficiency issues to persist in daily operations. So how can businesses ensure their warehouses operate efficiently while maintaining a safe working environment for employees?

Warehouse inspections serve as indispensable tools for safeguarding employee safety, protecting inventory from loss, and enhancing overall operational efficiency.

What Are Warehouse Inspections?

Warehouse inspections, also known as "warehouse audits," represent systematic evaluation processes designed to identify risks, ensure safety, protect inventory, and optimize internal warehouse procedures. These inspections encompass multiple aspects including:

- Inventory and storage management

- Employee safety and health

- Order fulfillment process efficiency

- Equipment maintenance and operation

- Application of technology and warehouse automation

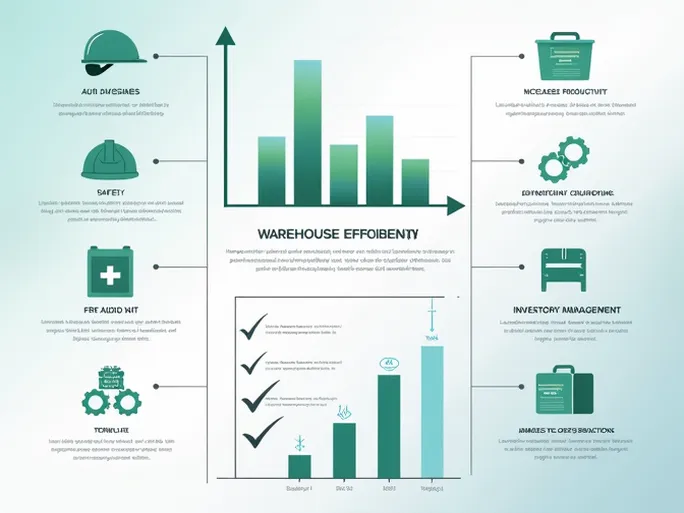

The Importance of Warehouse Inspections

1. Enhancing Productivity and Supply Chain Resilience

The primary objective of warehouse inspections is to ensure employee safety while optimizing business processes. Through standardized inspections, companies can significantly boost production efficiency while strengthening supply chain resilience and reducing operational costs. This continuous inspection mechanism helps businesses maintain competitiveness in an increasingly challenging market.

2. Compliance with Safety Standards and Legal Risk Reduction

Regular warehouse inspections help companies meet regulatory safety standards, identify potential hazards, and implement preventive measures to reduce accident risks. Failure to comply with these standards may lead to legal consequences, damage corporate reputation, and jeopardize financial stability—all critical factors for sustainable development.

3. Identifying Efficiency Improvement Opportunities

Warehouse inspections extend beyond safety reviews to efficiency discoveries. By examining operational workflows, businesses can pinpoint efficiency bottlenecks and implement corrective measures. These improvements can reduce operational expenses while substantially increasing customer satisfaction.

4. Time Investment and Attention to Detail

While the benefits of warehouse inspections are evident, the challenges are equally apparent. Thorough inspections demand significant time and resource investments, requiring meticulous examination of every operational aspect. This attention to detail may temporarily disrupt daily operations but proves essential for ensuring long-term efficiency.

5. Preventing Accidents and Compliance Risks

Ultimately, warehouse inspections effectively prevent accidents and mitigate legal risks associated with non-compliance. Ensuring all operations and equipment undergo proper audits not only safeguards employees but also establishes a solid foundation for long-term business operations.

Five Essential Warehouse Inspections

To maintain efficient and safe warehouse operations, these five fundamental inspections are indispensable:

- Inventory management: Ensure all inventory records are accurate and prevent expired or damaged goods.

- Safety training: Conduct regular employee training to enhance awareness of safety protocols.

- Equipment maintenance: Perform routine inspections and maintenance to keep all equipment in optimal condition.

- Sanitation checks: Regularly assess warehouse cleanliness and safety conditions to meet health standards.

- Process audits: Evaluate all workflows to identify improvement opportunities.

Five Key Elements of Effective Warehouse Inspections

When conducting warehouse inspections, these critical elements must be considered:

- Comprehensiveness: Ensure inspections cover all operational aspects without oversight.

- Regularity: Adjust inspection frequency based on operational needs to promptly address potential risks.

- Data-driven approach: Utilize analytical tools to support inspections and provide evidence-based insights.

- Team collaboration: Involve all relevant departments to enhance inspection effectiveness.

- Innovation: Encourage new methodologies and ideas for continuous warehouse improvement.

Frequently Asked Questions

To better understand the practical application of warehouse inspections, here are answers to common questions:

How frequently should warehouse inspections occur?

Inspection frequency should be determined based on warehouse size, product types, and business requirements. A comprehensive inspection at least monthly is generally recommended.

How should inspection results be evaluated?

Effectiveness can be assessed by comparing historical data, collecting employee feedback, and monitoring process improvements resulting from inspections.

By implementing these measures, businesses can reduce operational risks, improve efficiency, and continuously adapt to market developments—laying a solid foundation for future growth.