In modern logistics systems, effectively managing storage space and material flow has become a critical challenge for businesses. Today, we explore a widely used storage method—the dual-warehouse approach—that helps companies better manage inventory, improve logistics efficiency, and enhance market competitiveness.

What Is the Dual-Warehouse Method?

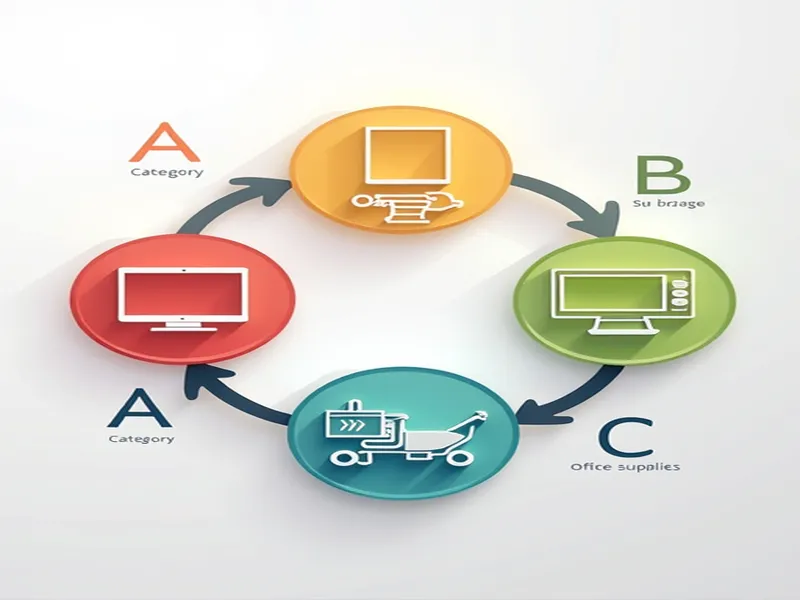

The core principle of the dual-warehouse method lies in effective inventory classification and management. It emphasizes categorizing inventory into different groups (typically A, B, and C classes) based on item importance and demand frequency. This classification approach, known as ABC analysis, is a fundamental tool in modern inventory management.

The Significance of ABC Analysis

In ABC analysis:

- Class A items are typically high-value but low-frequency usage products, such as premium equipment and spare parts;

- Class B items represent moderate-value and moderate-frequency products, like commonly used mechanical components;

- Class C items are low-value but high-frequency usage goods, including everyday office supplies.

This classification enables businesses to develop tailored management strategies for different product categories, thereby improving storage efficiency.

Implementing the Dual-Warehouse Method

The key to implementing this approach lies in determining appropriate inventory levels for each category. To avoid excessive inventory costs, companies can gradually work toward zero inventory targets. This doesn't mean eliminating inventory entirely, but rather maintaining minimum safety stock levels through accurate demand forecasting and timely replenishment.

Advantages of Centralized Inventory

In pursuit of economies of scale, moderately centralized inventory strategies prove crucial. Centralized management not helps reduce storage and transportation costs but also significantly improves dispatch efficiency. By minimizing inventory at each storage point, companies can respond more quickly to market changes.

However, excessive centralization carries potential risks. Increased transportation distances between storage points may lead to higher shipping costs. Therefore, businesses must find an optimal balance that maintains efficiency without causing disproportionate cost increases.

Balancing and Optimization

Moderately centralized inventory management doesn't blindly pursue quantity concentration but rather adapts flexibly based on customer needs and market conditions. For instance, companies should consider customer geographic distribution, ensuring adequate inventory in high-demand regions to minimize transportation costs while improving service quality.

Additionally, planning appropriate infrastructure is essential for optimizing inventory management. Site selection should consider not just geography but also logistics costs, transportation convenience, and market demand. Such comprehensive evaluation can significantly improve operational efficiency and lay a solid foundation for business growth.

Improving Turnover Speed

Another critical aspect of modern storage management involves accelerating turnover rates. Faster turnover speeds up capital flow, reduces product loss, increases warehouse throughput capacity, and lowers overall operating costs.

Dynamic Storage Methods

To achieve dynamic inventory management, adopting advanced technologies like unit container storage and rapid sorting systems is essential. These systems enable quick response to market demands and efficient product turnover. For example, unit container storage maximizes space utilization, while rapid sorting systems enhance inbound and outbound efficiency.

Implementing "first in, first out" (FIFO) management strategies also proves vital for efficient turnover. Ensuring products are used in chronological order helps control storage duration and reduces economic losses from expiration or damage. Effective FIFO implementation can be achieved through through-type shelf systems, dual-warehouse methods, and computerized access management.

These methods not guarantee orderly product handling but also combine rapid turnover with proper storage, continuously accelerating circulation while reducing labor costs.

Applications of Modern Storage Technology

In practice, many companies now employ modern technologies to enhance dual-warehouse efficiency. Smart warehouse systems, for instance, make product handling more intelligent and automated. These systems can monitor real-time inventory changes, automatically adjust storage strategies, and maintain optimal stock levels.

Furthermore, big data analytics enables better demand forecasting. By analyzing historical data, businesses can more accurately predict future needs, adjust inventory levels accordingly, and avoid unnecessary accumulation and losses.

Conclusion

The dual-warehouse method, as an effective inventory management approach, combines proper management mechanisms and technological optimization to improve logistics efficiency while reducing operating costs, providing strong support for sustainable business development. In future competition, companies that skillfully apply inventory management strategies will undoubtedly gain market advantages.

As a science communicator, we hope this in-depth analysis helps more businesses understand the potential and importance of the dual-warehouse method. In today's rapidly evolving technological landscape, properly leveraging modern tools to enhance overall management capabilities has become imperative. As market competition intensifies, only those who keep pace with the times and embrace innovation will maintain industry leadership.