Shipping containers serve as the standardized bricks of global trade, supporting vast logistics networks. However, how well do you understand the dimensions, codes, and optimal loading strategies for different container types? This article provides an in-depth analysis of common container specifications to enhance efficiency in freight forwarding operations.

Containers: The Standardized Foundation of Global Commerce

Imagine a massive vessel arriving from distant ports, laden with diverse cargo. The safe and efficient transportation of these goods largely depends on container standardization. The advent of shipping containers has dramatically simplified loading/unloading processes, reduced cargo damage rates, and accelerated the flourishing development of global trade.

Detailed Specifications of Three Standard Shipping Container Types

The three most common standard shipping containers are 20GP (20-foot general purpose), 40GP (40-foot general purpose), and 40HQ (40-foot high cube). They differ in size, payload capacity, and are suited for different cargo types. The following table provides detailed comparisons:

| Specification | 20GP (20-foot GP) | 40GP (40-foot GP) | 40HQ (40-foot High Cube) | Notes |

|---|---|---|---|---|

| External Dimensions | ||||

| Length | 20 ft (6.1 m) | 40 ft (12.2 m) | 40 ft (12.2 m) | 20-ft container is half the length of 40-ft |

| Width | 8 ft (2.44 m) | 8 ft (2.44 m) | 8 ft (2.44 m) | All share same width |

| Height | 8.5 ft (2.6 m) | 8.5 ft (2.6 m) | 9.5 ft (2.9 m) | High cube is 1 ft taller |

| Internal Dimensions | ||||

| Length | 6 m | 12 m | 12 m | |

| Width | 2.35 m | 2.35 m | 2.35 m | |

| Height | 2.39 m | 2.39 m | 2.70 m | |

| Payload | ~26 tons | ~26 tons | ~28 tons | |

| Tare Weight | 2.2 tons | 3.8 tons | 3.9 tons | |

| Door Height | 2.28 m | 2.28 m | 2.56 m | |

| Door Width | 2.34 m | 2.34 m | 2.34 m | |

| Internal Volume | 33.1 m³ | 67.5 m³ | 75.3 m³ | |

| Practical Capacity | ~30 m³ | ~63 m³ | ~72 m³ |

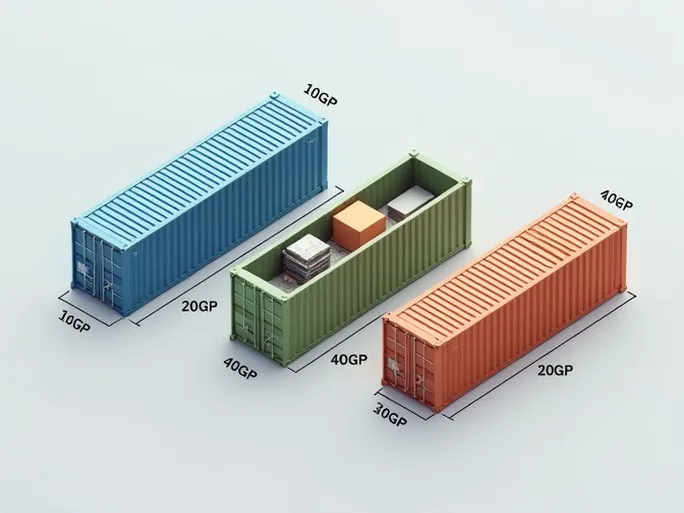

Visual Representation of Dimensions

- 20GP: 20 ft (L) × 8 ft (W) × 8.5 ft (H)

- 40GP: 40 ft (L) × 8 ft (W) × 8.5 ft (H)

- 40HQ: 40 ft (L) × 8 ft (W) × 9.5 ft (H)

Unit Conversion Guide

Common conversion formulas for practical operations:

- 1 inch = 2.54 cm

- 1 foot = 12 inches = 30.48 cm

Calculating Container Dimensions

With unit conversions, container measurements become straightforward:

- Width: 8 ft = 2.438 m

- Standard height: 8 ft 6 in = 2.59 m

- High cube height: 9 ft 6 in = 2.89 m

- 20-ft length: 20 ft = 6.096 m

- 40-ft length: 40 ft = 12.192 m

Container Volume (CBM) Calculation

Volume is crucial for assessing loading capacity:

- 20GP volume ≈ 38.5 m³ (practical capacity ~30 m³)

- 40GP volume ≈ 77 m³ (practical capacity ~65 m³)

- 40HQ volume ≈ 86 m³ (practical capacity ~75 m³)

45HQ Container Specifications

Beyond standard containers, 45HQ is gaining popularity:

- Length: 45 ft = 13.716 m

- Volume ≈ 96 m³ (practical capacity ~85 m³)

Eight Common Container Types and Their Codes

Container codes indicate type and characteristics (20-ft examples shown):

| Container Type | Code | 95 Code |

|---|---|---|

| Dry Container | GP | 22G1 |

| High Cube Dry | GH/HC/HQ | 25G1 |

| Hanger Container | HT | 22V1 |

| Open Top | OT | 22U1 |

| Reefer | RF | 22R1 |

| High Cube Reefer | RH | 25R1 |

| Tank | TK | 22T1 |

| Flat Rack | FR | 22P1 |

Decoding 95 Codes

- Codes beginning with 2: 20-ft containers

- Codes beginning with 4: 40-ft containers

- Codes beginning with L: 45-ft containers

- Second digit 2: Standard height (8.5 ft)

- Second digit 5: High cube (9.5 ft)

Container Loading Optimization Strategies

Understanding specifications enables efficient loading:

- Cargo Matching: Select container types based on dimensions, weight, and characteristics

- Space Utilization: Maximize internal space with proper packing materials

- Weight Distribution: Ensure balanced loading to prevent instability

- Loading Sequence: Arrange cargo according to unloading requirements

- Securing Measures: Implement appropriate restraints for fragile items

Container Selection by Cargo Type

- Apparel: Hanger containers prevent garment wrinkling

- Frozen Goods: Reefers maintain required temperatures

- Heavy Machinery: Flat racks facilitate loading/unloading

- Liquids: Tank containers prevent leaks

Mastering container specifications, codes, and loading techniques forms the foundation of freight forwarding expertise. Proper container selection and optimized loading strategies enhance operational efficiency, reduce costs, and improve service quality. This comprehensive guide serves as a valuable reference for professionals in global logistics.