In contemporary logistics and warehouse management, medium and heavy duty shelving systems have gained prominence due to their exceptional versatility. Designed specifically for storing heavier items, these systems offer distinct advantages despite their relatively lower storage density compared to other racking types. Characterized by remarkable load-bearing capacity, broad adaptability, and operational efficiency, these racking solutions are widely implemented across industrial manufacturing, third-party logistics, and distribution centers. They accommodate diverse storage needs ranging from multiple small-batch items to limited quantities of bulk goods.

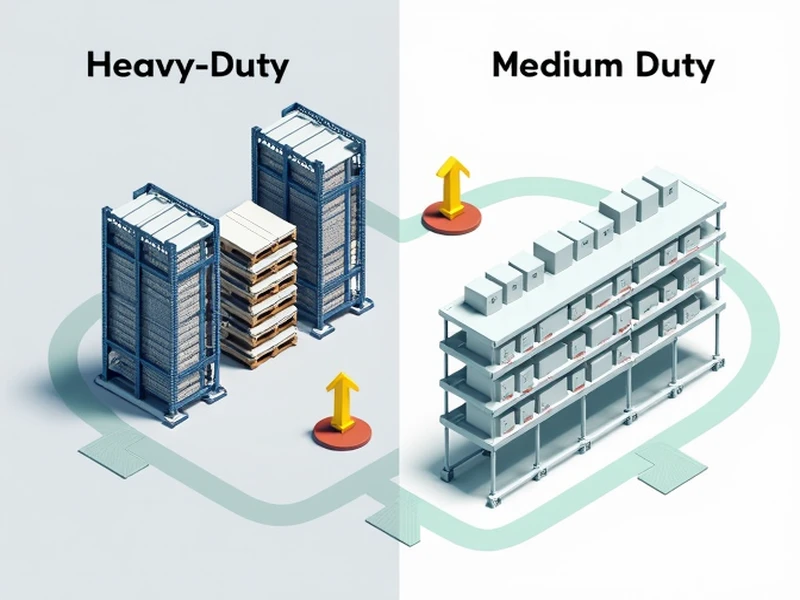

Two Primary Variants: Heavy Duty vs Medium Duty Racking

The heavy duty racking system excels in large-scale industrial facilities and high-bay warehouses. Typically accessed via pallets and forklifts, these robust structures boast an impressive load capacity of up to 4 tons per level, with stringent design requirements. Their vertical efficiency allows optimal utilization of overhead space, reaching single-section heights of 10 meters. Engineered for stability and safety, these adjustable-height systems facilitate streamlined inventory management.

In contrast, medium duty racking features a modular boltless assembly design that simplifies installation and offers flexible configuration options. With uniform height adjustability and lighter overall weight, these systems provide a practical solution for various industries. Their maximum single-layer capacity of 500 kilograms makes them the preferred choice for small to medium-sized warehousing operations.

Critical Safety Considerations

Both heavy duty and high-bay racking systems demand strict adherence to safety protocols:

- Operate strictly within rated load capacities to prevent structural overload

- Verify item dimensions comply with ideal specifications to avoid protrusion beyond shelf width

- Forklift operators must exercise caution during handling to minimize impact damage

- Standardized pallets must be employed to ensure even weight distribution

- Personnel should avoid lingering beneath racking structures to prevent potential accidents

These operational best practices not only enhance warehouse safety but also safeguard employee wellbeing. By implementing these fundamental principles, facilities can maintain efficient storage management while ensuring a secure working environment.