Wooden pallets, primarily constructed from natural timber, serve as fundamental tools in modern logistics and warehousing operations. Their unique characteristics and versatility have made them indispensable across various industries. Based on construction materials, pallets are generally categorized into three types: wooden, plastic, and metal. Among these, wooden pallets remain the preferred choice for many businesses due to their exceptional strength, load-bearing capacity, and cost-effectiveness.

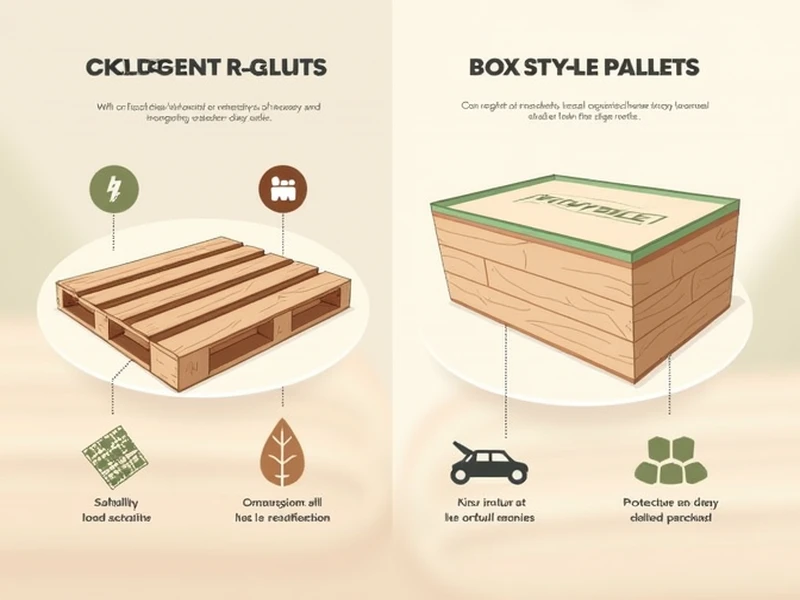

Structural Varieties: Post Pallets vs. Box Pallets

Post pallets represent a significant category of wooden pallets. Their fundamental structure consists of four steel corner posts supporting multiple horizontal beams, creating a stable framework. This design excels in maintaining cargo stability during transportation and handling operations, effectively preventing load collapse and ensuring transport safety. When stacking multiple post pallets, their structural integrity significantly reduces risks of tilting or toppling.

These pallets are particularly suitable for heavy-duty applications requiring high stacking capacity, making them essential in warehouse logistics, heavy industry, and manufacturing sectors. They commonly transport heavy machinery and large-scale equipment where stability under substantial weight is paramount.

Box pallets constitute another critical pallet type, distinguished by their perimeter side panels that provide superior cargo protection during transit. These side panels come in three configurations: fixed, collapsible, and removable—each serving specific operational requirements. Fixed panels offer permanent protection for long-term storage and shipping, while collapsible and removable variants provide operational flexibility for diverse usage scenarios.

When selecting box pallets, consideration must extend to panel designs—available in solid board, mesh, or grid patterns. These variations impact both cargo visibility and ventilation needs, particularly crucial when transporting perishable goods where proper airflow can significantly extend product shelf life. With their enhanced protective capabilities, box pallets are ideal for irregularly shaped items, finding applications across agriculture, automotive components, and electronics industries.

Operational Best Practices

To maximize wooden pallet performance and longevity, several operational guidelines merit attention. First, direct sunlight exposure should be avoided, especially during summer months, as intense heat accelerates wood aging and deformation, prematurely shortening service life. Second, cargo loading requires careful placement—goods should be centrally positioned with even weight distribution rather than being dropped from height, minimizing tipping risks.

Forklift operations demand particular precision: ensure complete fork insertion before lifting and maintain careful handling to prevent pallet or cargo damage. Equally critical is observing racking capacity limits—overloading poses serious safety hazards that businesses must conscientiously avoid.

Strategic Selection and Sustainability

In conclusion, wooden pallets maintain undeniable importance in logistics operations. Both post and box pallets offer distinct advantages tailored to specific applications, enabling businesses to select optimal solutions based on cargo characteristics, transportation requirements, and operational workflows. Through proper selection, conscientious usage, and systematic maintenance, wooden pallets can achieve maximum service life and operational efficiency, serving as sustainable pillars in modern supply chain management.