In modern logistics, transporting batteries—especially lithium batteries—is far from simple. A single mistake can lead to cargo fines, fires, or even complete shipping bans. Why is this area so challenging? Batteries are classified as dangerous goods due to their high risk of ignition and explosion. This classification means stricter regulations must be followed regarding packaging, labeling, documentation, and carrier approval. This article provides an in-depth analysis of battery classification, mode-specific transportation rules, and best practices for safe shipping to ensure compliance and avoid delays.

Why Is Battery Transportation So Challenging?

Battery transportation, particularly lithium batteries, poses significant safety risks if mishandled. These batteries can cause fires, leaks, or short circuits, classifying them as dangerous goods (DG) that require strict shipping regulations. Improper packaging or declaration can result in:

- Thermal runaway, fires, or explosions during transit

- Cargo damage due to battery leakage or overheating

- Injuries to handlers or emergency responders

- Fines, delays, or shipment rejections due to non-compliance

- Emergency landings or ship diversions in extreme cases

Most lithium batteries are classified as Class 9 dangerous goods, but specific handling requirements depend on factors like battery chemistry (lithium-ion vs. lithium metal), condition (new, used, or damaged), and whether they're shipped alone, installed in equipment, or packed with devices.

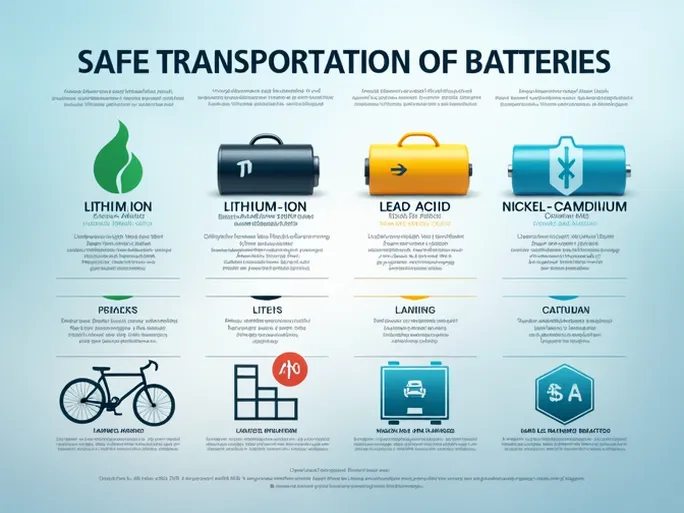

How Are Batteries Classified for Transportation?

Different battery types present varying risks, affecting their packaging, labeling, and shipping requirements. Below is a quick guide to common battery types and their transportation classifications:

| Battery Type | UN Number | Examples | DG Class | Notes |

|---|---|---|---|---|

| Lithium-ion | UN 3480 / UN 3481 | Smartphones, laptops, e-bikes, EVs | Class 9 | High energy density; air transport limited to 30% charge; damaged/recalled batteries need special handling. |

| Lithium metal | UN 3090 / UN 3091 | Watches, medical implants, GPS devices | Class 9 | Stricter rules than lithium-ion, especially for air transport with permanent quantity limits. |

| Lead-acid | UN 2794 / UN 2800 | Car batteries, backup power systems | Class 8 | Corrosive and leak-prone; must be kept upright during transport with ventilation. |

| Nickel-cadmium | UN 2795 | Industrial tools, aviation equipment | Class 8 | Corrosive; free-flowing electrolytes require Class 8 packaging rules. |

| Nickel-metal hydride | UN 3496 | Power tools, consumer electronics | Non-DG* | Generally unregulated but carrier/local rules may apply. |

| Alkaline (dry cell) | Unregulated** | AA/AAA batteries, household electronics | Non-DG | Typically unregulated unless damaged, leaking, or bulk-shipped. |

* Nickel-metal hydride batteries are generally unregulated by international law but always verify with carriers, especially for air transport.

** All damaged or defective batteries are considered high-risk and require special approval, packaging, and labeling.

Preparing Batteries for Transportation

Follow these steps to ensure compliant, safe battery shipments:

1. Identify Battery Type and Classification

First, determine the battery type you're shipping. You'll need to know:

- Chemical composition (e.g., lithium-ion, lithium metal)

- Specifications (UN number, watt-hour rating)

- Packaging method (alone, with equipment, or installed)

- Condition (new, used, damaged, or defective)

This information determines applicable regulations and how batteries must be handled and declared.

2. Use Compliant Packaging

Proper packaging prevents leaks, short circuits, and fires. Ensure:

- Batteries are placed in inner packaging (e.g., cardboard, plastic, or blister packs)

- Sufficient cushioning prevents movement

- All items are in sturdy outer packaging (cardboard, wood, or metal)

- Terminals are protected with caps or insulation to prevent shorting

- Packages remain upright and away from heat sources

Damaged or leaking batteries require UN-certified packaging with absorbent materials and leak-proof seals.

3. Apply Correct Labels and Markings

Ensure clear labeling including:

- Proper UN number (e.g., UN3480 for lithium-ion)

- Correct shipping name (e.g., "Lithium-ion batteries")

- Hazard labels (Class 9 for lithium, Class 8 for others)

- Lithium battery handling label (if required)

- Orientation arrows (when applicable)

- 24/7 emergency response phone number

Use waterproof or plastic labels, and avoid placing them on removable/temporary packaging like shrink wrap.

4. Prepare Accurate Documentation

Depending on battery type and transport method, shipments may require:

- Dangerous Goods Declaration (DGD)

- Material Safety Data Sheet (MSDS) or Safety Data Sheet (SDS)

- Battery test summary (proving UN 38.3 compliance for lithium batteries)

- Emergency response guide (for fire/damage handling)

- Shipping reservation documents with UN number and description

- Pilot notification (for air transport)

- Packaging certification (for UN-certified materials)

- Government exemptions or special approvals (for damaged/defective batteries)

Recommendation: Always verify latest requirements for destinations and transport modes as regional and carrier rules vary.

Choosing a Transportation Mode

Batteries can be shipped via different methods, each with distinct rules:

| Transport Mode | Governing Regulations | Notes |

|---|---|---|

| Air | IATA DGR and IATA Lithium Battery Shipping Regulations (LBSR) | Most restrictive; state of charge (SOC) ≤ 30%. Damaged batteries prohibited. |

| Ocean | IMDG Code (International Maritime Dangerous Goods) | Allows bulk shipments with proper declaration, labeling, and packaging compliance. |

| Road | ADR (Europe), DOT regulations (US) | Country-specific weight, quantity, and segregation limits. Route planning is critical. |

| Rail | RID (Europe), FRA (US), and regional equivalents | Similar to road regulations but with regional variations in restrictions and documentation. |

Not all battery types can be air-shipped. For example, lithium batteries above certain watt-hour ratings must go by ocean or road. Some airlines may impose stricter rules than IATA.

Key Differences Between Air and Ocean Lithium Battery Transport

Below are critical regulatory differences for shipping lithium batteries by air versus ocean:

| Requirement | Air (IATA) | Ocean (IMDG) |

|---|---|---|

| State of Charge (SOC) Limit | ≤ 30% for standalone batteries | No SOC requirement |

| Damaged Batteries | Prohibited | Allowed with special packaging |

| Packaging | Strict inner/outer requirements | More flexible packaging rules |

| Labeling | Mandatory with size specifications | Mandatory but format-flexible |

| Documentation | Highly stringent | Moderately stringent |

Best Practices for Safe Battery Transportation

To ensure compliance and avoid disruptions, follow these industry best practices:

- Train your team: Personnel handling battery shipments must receive DG training, with emergency response plans and SOPs.

- Proper isolation and labeling: Use certified battery packaging and accurate documentation, keeping shipments away from flammables and heat sources.

- Avoid shipping damaged batteries: Never ship swollen, leaking, or recalled batteries without approval.

- Review before each shipment: Regulations change frequently; check IATA/IMDG updates for compliance.

Conclusion

Battery transportation isn't standard logistics—it's a high-risk, high-compliance operation requiring precision at every step. From correct classification and certified packaging to proper documentation and safe transport methods, each phase is critical. For assistance with safe battery shipping, stay informed about compliance processes and safety measures.