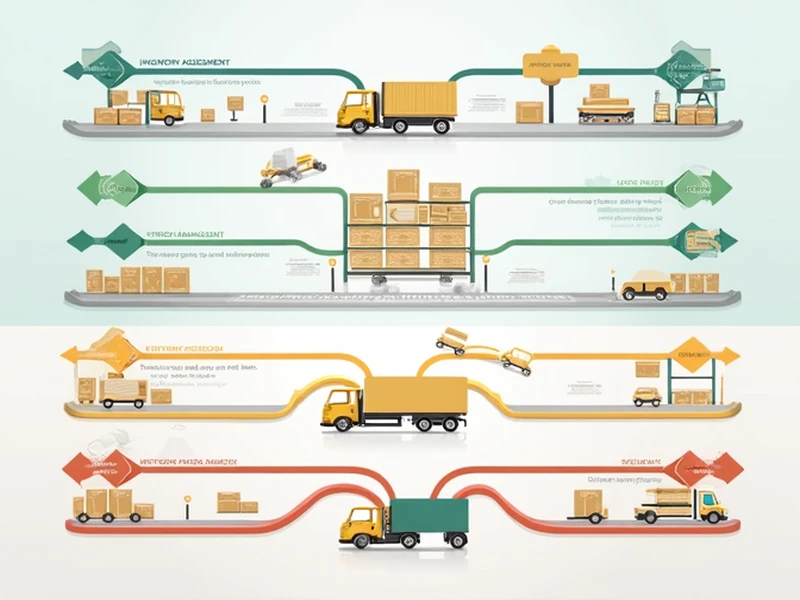

In contemporary logistics management, distribution operations stand as one of the central pillars of supply chain systems. The scientific and rational execution of these processes not directly impacts corporate profitability but also significantly influences customer satisfaction. Therefore, systematic analysis of each logistics distribution segment and in-depth exploration of implementation strategies become paramount.

I. Procurement: Foundation and Challenges

Procurement constitutes the initial phase of logistics distribution, primarily involving resource mobilization and preparation based on market demand forecasts. The quality and efficiency of procurement directly affect subsequent distribution processes, ultimately determining the overall standard of logistics services. Typically, procurement encompasses multiple sub-processes: ordering, collection, receipt, quality inspection, and settlement of goods.

1.1 Demand Forecasting and Resource Allocation

The primary task in procurement lies in accurate demand forecasting. This requires analyzing market trends, historical sales data, and seasonal fluctuations to develop scientific procurement plans. The precision of demand forecasting often becomes the decisive factor affecting both inventory costs and customer satisfaction. By implementing advanced forecasting techniques (such as data mining and machine learning), enterprises can enhance prediction accuracy, avoiding excessive inventory buildup and stockouts.

1.2 Supply Chain Collaboration

Effective communication and coordination with suppliers remains critical during procurement. Selecting appropriate suppliers and establishing robust partnerships ensures stable and timely material supply. Companies may employ long-term contracts or create information-sharing platforms to guarantee efficient supply chain operations while reducing uncertainty.

1.3 Cost Control

Cost management in procurement proves essential. High inventory costs not only impair distribution efficiency but may also lead to resource wastage. Through scientific inventory management methods like ABC classification or economic order quantity models, businesses can effectively reduce holding costs while maintaining procurement efficiency.

II. Storage: Responsiveness and Flexibility

The storage phase serves as another crucial step in distribution, responsible for maintaining adequate reserves to meet delivery demands. In practice, storage typically manifests in two forms: bulk reserves ensuring distribution fluidity, and temporary storage generated during sorting operations.

2.1 Bulk Reserve Strategies

Bulk reserves enable rapid response to market fluctuations during peak periods. Enterprises must evaluate the balance between storage costs and service levels to formulate appropriate inventory strategies, often involving storage facility selection and layout design.

2.2 Temporary Storage Management

Though frequently overlooked, temporary storage—typically smaller in scale—plays a vital role in synchronizing sorting and delivery rhythms. Efficient temporary storage management requires integration with modern information systems for real-time inventory tracking and quick demand response.

III. Sorting and Allocation: Efficiency Multipliers

Sorting and allocation represent pivotal steps in achieving efficient distribution, involving classification, consolidation, and deployment of goods that directly impact delivery accuracy and service quality.

3.1 Modern Sorting Technologies

Automated sorting systems utilizing advanced algorithms and precision equipment can process orders rapidly, reducing human error and labor costs while significantly improving efficiency.

3.2 Workforce Training

Despite technological advancements, human operators remain indispensable in sorting operations. Companies should invest in comprehensive training programs to enhance workers' skills and accountability, ensuring packaging standards that ultimately elevate consumer satisfaction.

3.3 Allocation Strategy Optimization

The scientific design of allocation strategies directly influences distribution outcomes. By employing various methodologies (minimum cost, shortest time, etc.), businesses can select solutions aligning with their operational models and customer requirements, guaranteeing efficient and accurate deliveries.

IV. Loading: Transport Resource Optimization

Loading forms an integral component of distribution, combining shipments for multiple customers to maximize transportation resource utilization.

4.1 Loading Strategies

Effective loading considers not just cargo dimensions but also specific client needs. Logistics managers must possess specialized knowledge to develop optimal loading plans, with research demonstrating that scientific approaches reduce costs and enhance transport efficiency.

4.2 Information Systems in Loading

Information systems prove invaluable for loading decisions. Historical data analysis enables route efficiency predictions and timely loading adjustments for optimal resource allocation.

V. Transportation: Route and Mode Selection

The transportation phase physically moves goods from warehouses to customers, with urban route complexity directly affecting delivery efficiency and satisfaction levels.

5.1 Route Optimization Algorithms

Optimal route selection serves as the cornerstone of transport efficiency. Pathfinding algorithms (Dijkstra's, genetic algorithms, etc.) enable scientific route planning that reduces transit times while improving efficiency—particularly valuable in congested urban environments.

5.2 Transport Mode Selection

Choosing appropriate transport vehicles remains critical. Businesses must select modes (trucks, drones, robots, etc.) matching their industry characteristics and market demands to minimize costs while maximizing efficiency.

VI. Delivery: Prioritizing User Experience

As the final distribution phase, delivery service quality critically impacts user experience, encompassing handover, receipt confirmation, and related procedures.

6.1 Unloading Location Optimization

Identifying appropriate unloading points and methods forms the foundation of quality delivery service. Through proactive customer communication, logistics providers can determine optimal unloading solutions that enhance final-mile efficiency.

6.2 Communication Protocols

Seamless information exchange between customers and providers proves essential for satisfactory delivery experiences. Logistics firms should establish convenient communication channels for real-time shipment updates and query resolution throughout the delivery process.

VII. Conclusion and Future Outlook

From procurement through final delivery, each phase constitutes an indispensable component of logistics distribution. Scientific management and coordination significantly enhance both corporate competitiveness and customer satisfaction. As technology continues evolving, distribution processes will grow increasingly efficient and intelligent. Logistics enterprises must actively embrace innovation to maintain market advantage and achieve sustainable growth. In our rapidly changing commercial landscape, companies must remain agile, customer-centric, and committed to continuous improvement to meet ever-more diverse and personalized consumer demands.