Risk Management Crucial for Safe Goods Loading and Unloading

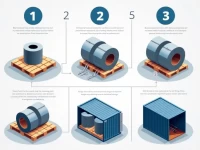

Loading and unloading protection offers comprehensive coverage for goods in transit, preventing losses and risks during the handling process. This protection is crucial for ensuring cargo safety, reducing financial pressure on businesses, and enhancing customer trust and company reputation.