In modern supply chain operations, warehouse management has become a critical competitive differentiator. Among its most consequential elements is order picking efficiency —a process that directly impacts operational costs, delivery speed, and ultimately, customer satisfaction. The strategic design of picking paths isn't just about resource optimization; it's a cornerstone of service experience.

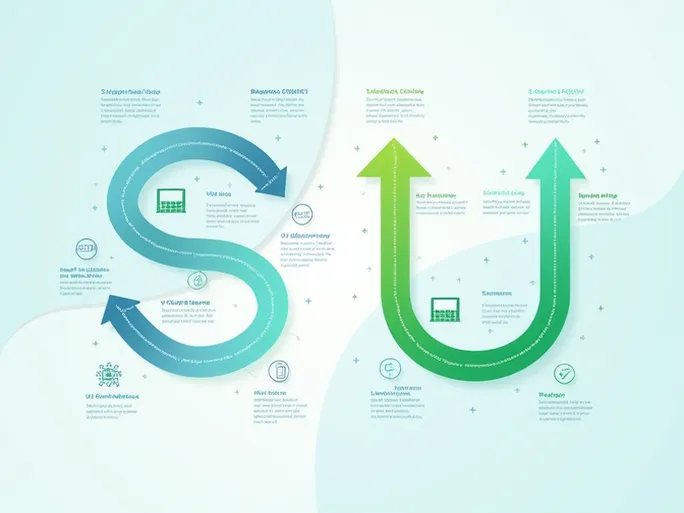

Two dominant methodologies have emerged in warehouse design: the serpentine S-shaped path and the looped U-shaped alternative . As businesses navigate evolving market demands, the question of which approach delivers superior efficiency has become a pressing operational dilemma.

The Case for S-Shaped Paths

The S-shaped configuration—where pickers traverse alternating aisles in a continuous snaking pattern—boasts compelling geometric advantages. "In traditional single-aisle layouts, the S-path minimizes travel distance by applying the fundamental principle that the shortest distance between two points is a straight line," explains warehouse design expert David Muller. This proves particularly effective for facilities with high-velocity SKUs concentrated in specific zones.

However, real-world implementation reveals limitations. During peak periods like Black Friday or Singles' Day, S-paths frequently develop congestion points as pickers cross paths in narrow aisles. A 2022 logistics study found that pick-time variability increases by 18-22% in S-configured warehouses during high-volume periods due to worker collisions and bottleneck formation.

U-Shaped Paths: Flexibility Meets Efficiency

U-shaped designs counter these challenges through modular workflow organization. By positioning high-demand SKUs along the base of the "U" near packing stations, warehouses can reduce average walking distance by 15-30% for priority items. The open-ended structure also allows dynamic rerouting around congestion.

"What makes U-paths revolutionary isn't just distance savings," notes supply chain technologist Maria Chen. "Their inherent flexibility enables real-time adjustments—when combined with RFID and vision-picking systems, we've seen 30% fewer mispicks compared to traditional layouts."

Beyond Geometry: The Tech Factor

Modern warehouses increasingly blend path design with advanced technologies:

•

RFID tracking

enables real-time inventory visibility across both path types

•

Augmented reality

guides pickers through optimized routes

•

Predictive analytics

adjust SKU placement based on sales trends

These innovations create hybrid models where path geometry becomes just one variable in a larger efficiency equation. Amazon's Kiva-powered facilities, for instance, use mobile shelving to dynamically reshape picking paths based on real-time demand.

The Verdict: Context is King

Operational leaders emphasize that optimal path selection depends on multiple factors:

•

SKU velocity patterns

(stable vs. seasonal)

•

Facility dimensions

(aisle width, vertical storage)

•

Order profile complexity

(single-line vs. multi-item picks)

•

Technology integration

level

Progressive warehouses now employ adaptive zoning —using temporary cross-aisles in S-paths during peaks or implementing convertible U/S hybrid layouts. As global logistics face growing pressure, the winning strategy lies not in rigid adherence to one model, but in building agile systems that evolve with market demands.

The future belongs to warehouses that treat path optimization as a continuous process rather than a fixed design choice—where geometry meets artificial intelligence to redefine efficiency standards.