The rubber and plastics industry is undergoing unprecedented transformation as environmental regulations tighten and cost pressures mount. China's decision to eliminate the 13% VAT export rebate for PVC products effective April 1, 2026, delivers a significant blow to PVC manufacturers, particularly small and medium enterprises where exports account for over 30% of business.

PVC Industry Challenges: Cost, Environmental and Policy Pressures

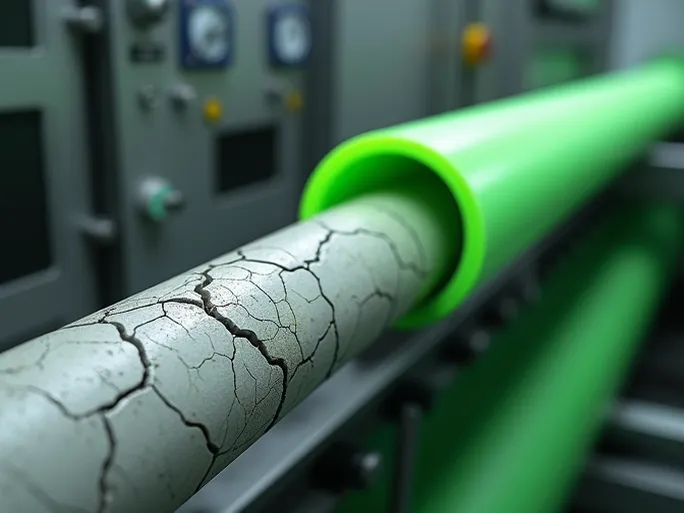

PVC, a widely used plastic in construction, packaging and consumer goods, faces growing scrutiny due to environmental concerns. Its production involves toxic chemicals like vinyl chloride, while traditional PVC products often contain phthalate plasticizers that may migrate and pose health risks. Additionally, PVC combustion releases harmful gases.

The rebate cancellation compounds existing challenges for PVC producers. A 1-2% cost increase directly impacts international competitiveness for exporters, while domestic oversupply and high inventory levels exacerbate market pressures. Stricter environmental policies further necessitate substantial compliance investments, accelerating industry consolidation.

TPE Alternatives Gain Momentum with Environmental Advantages

Thermoplastic elastomers (TPE) are emerging as preferred substitutes in traditional PVC applications, offering superior environmental profiles and performance characteristics. TPE's non-toxic, recyclable and biocompatible properties meet stringent international standards, particularly in these sectors:

- Toys and Consumer Goods: TPE replaces PVC in children's products and food containers with odor-free, high-resilience alternatives that command premium pricing.

- Automotive Components: TPE's weather and heat resistance make it ideal for seals and hoses in demanding operating conditions.

- Medical Applications: Modified TPE formulations meet sterilization requirements for medical tubing and devices while reducing allergic reactions.

While TPE raw material costs remain higher than PVC, domestic SEBS (styrene-ethylene-butylene-styrene) technology advancements have narrowed the gap to within 15%. TPE's performance advantages in low-temperature resistance, aging prevention and biocompatibility make it particularly suitable for electric vehicles and advanced medical devices.

Toughening System Upgrades Drive PVC Replacement

The rebate cancellation accelerates PVC phase-outs in daily-use plastics, spurring adoption of alternative toughening systems:

- PS/ABS Materials: SBS copolymers provide optimal solutions with options ranging from transparent grades for packaging to high-impact versions for structural components.

- PP/PE Materials: POE elastomers offer excellent compatibility with polyolefins, enhancing low-temperature performance for films and containers.

- Outdoor Applications: SEBS systems deliver superior weatherability for long-service products while meeting food contact and toy safety standards.

Industry Transformation Pathways

Manufacturers must adapt to these structural changes through technical upgrades and market repositioning. TPE compounders should focus on formulation innovations and niche applications, while plastics processors need to select appropriate toughening systems based on product requirements. Companies that embrace material substitution and environmental compliance will be best positioned for sustainable growth.

The convergence of regulatory changes and market demand is reshaping the plastics landscape, with TPE and advanced toughening systems representing key growth areas in the industry's evolution toward more sustainable materials.