If your shipments consistently fail to fill containers despite meeting theoretical volume calculations, or if goods that should fit theoretically prove impossible to load practically, the root cause likely lies in insufficient understanding of shipping container specifications—particularly high cube containers. This analysis examines container dimensions from a data analyst's perspective, offering selection and loading optimization strategies to maximize space utilization and reduce transportation costs.

Container Standards: Beyond Length, Width, and Height

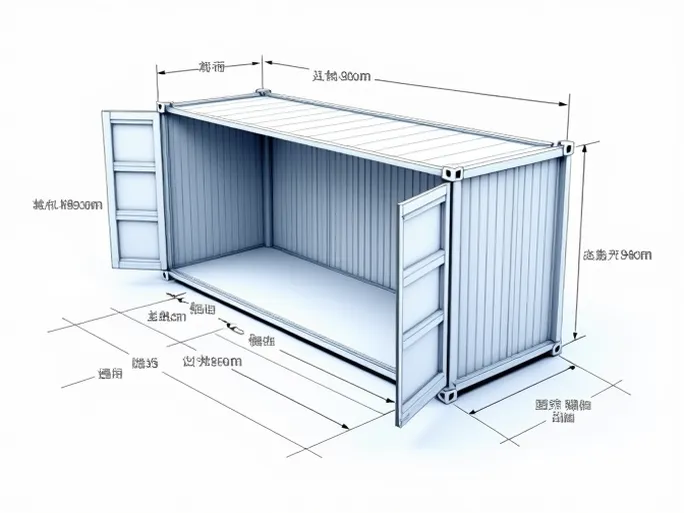

Shipping containers involve more than three basic measurements. Several critical parameters directly impact actual loading capacity:

- External Dimensions: The container's physical exterior measurements determine its footprint during maritime and land transportation, typically measured in feet (e.g., 20ft, 40ft).

- Internal Dimensions: The actual usable space for cargo, always smaller than external dimensions due to wall thickness and insulation. This is the crucial metric for loading calculations.

- Door Opening Dimensions: The portal through which goods enter/exit, particularly vital for oversized or irregularly shaped items.

- Maximum Payload: The weight limit that prevents safety violations and potential carrier rejections.

- Cubic Capacity: Total internal volume measured in cubic meters (CBM) or cubic feet, though actual loading efficiency depends on cargo shape and packaging.

High Cube Container Specifications: Decoding the 40HQ

The 40-foot high cube container (40HQ) dominates maritime shipping for tall cargo, offering approximately one foot more internal height than standard 40GP containers:

| Measurement | Unit | Value | Notes |

|---|---|---|---|

| External Length | mm | 12192 | Equivalent to 40 feet |

| External Width | mm | 2438 | 8 feet standard |

| External Height | mm | 2896 | 9'6" - 1 foot taller than 40GP |

| Internal Height | mm | 2698 | Critical for tall cargo |

| Door Height | mm | 2585 | Maximum entry clearance |

| Maximum Payload | kg | 26480-30480 | Varies by carrier and route |

| Theoretical Volume | CBM | 76.3 | Actual capacity depends on cargo characteristics |

Key Considerations: Manufacturer variations exist—always verify actual container markings. Exceeding weight limits incurs safety risks and penalties, while theoretical volumes rarely match real-world loading efficiency due to cargo irregularity.

Comparative Analysis: 20GP vs. 40GP vs. 40HQ

| Specification | 20GP | 40GP | 40HQ |

|---|---|---|---|

| Internal Length | 5898mm | 12032mm | 12032mm |

| Internal Height | 2393mm | 2393mm | 2698mm |

| Payload Capacity | 21600kg | 26480kg | 26480-30480kg |

| Theoretical Volume | 33.2 CBM | 67.7 CBM | 76.3 CBM |

Container Selection Methodology

Optimal container choice balances four factors:

- Cargo Dimensions: Height exceeding 2393mm necessitates 40HQ; lengthy items favor 40-foot containers.

- Weight Distribution: Heavy but compact shipments may optimize cost in 20GP containers.

- Special Requirements: Temperature control, ventilation, or hanging systems dictate specialized containers.

- Cost Efficiency: Smaller containers generally reduce freight expenses when operational needs allow.

Loading Optimization Techniques

Five strategies maximize space utilization:

- Packaging Geometry: Convert circular items to rectangular packaging and implement palletization.

- Strategic Stacking: Base layers for heavy items, segregated zones for irregular shapes, with stability prioritization.

- Void Minimization: Air cushions, foam, or cardboard fillers prevent cargo shift during transit.

- Loading Software: Advanced algorithms generate optimal cargo arrangements based on dimensional inputs.

- Weight Distribution: Balanced center of gravity prevents dangerous tilting during transport.

Specialized Container Applications

Beyond standard dry containers, specialized variants address unique needs:

- Reefer Containers: Temperature-controlled for perishables.

- Open-Top Containers: Removable roofing facilitates overhead loading.

- Flat Rack Containers: Collapsible sides accommodate oversized cargo.

- Tank Containers: Liquid transport with specialized containment systems.

- Garment Containers: Integrated hanging systems prevent clothing deformation.

Industry Evolution: Smart Containers and Standardization

The container industry progresses along two trajectories:

- Smart Containers: IoT-enabled units provide real-time monitoring of location, temperature, humidity, and shock detection.

- Global Standardization: Uniform dimensions and operational protocols enhance interoperability across transport networks.

Mastering container specifications and loading methodologies enables businesses to optimize logistics expenditure while improving supply chain efficiency. As container technology advances, these fundamentals will remain essential for global trade operations.