In the stormy seas of the global economy, businesses resemble surfers struggling to maintain balance amid unpredictable waves. When these waves grow erratic—suddenly swelling or shrinking without warning—the challenge becomes overwhelming, threatening to engulf even the most experienced riders. This precisely describes the current predicament facing global supply chains: a complex phenomenon known as the "bullwhip effect."

The COVID-19 pandemic unleashed an unprecedented tempest upon global supply networks. Minor fluctuations in consumer demand, amplified as they traveled up the supply chain, created massive imbalances between supply and demand that continue to hinder economic recovery worldwide. How can businesses regain control of this unwieldy "bullwhip" and navigate toward calmer waters?

Understanding the Bullwhip Effect: The Root of Supply Chain Disruptions

At its core, the bullwhip effect stems from distorted demand forecasting. Companies traditionally rely on historical sales data to predict future orders for raw materials or finished goods. However, when black swan events like a global pandemic strike, consumer behavior becomes erratic, rendering traditional forecasting models obsolete.

Each supply chain participant makes decisions based on incomplete information, creating a ripple effect that magnifies discrepancies. Purchase orders may bear little resemblance to actual demand; factories might overproduce to capitalize on perceived opportunities or underproduce to avoid excess inventory. Meanwhile, buyers might hoard products or scramble for substitutes, further destabilizing markets.

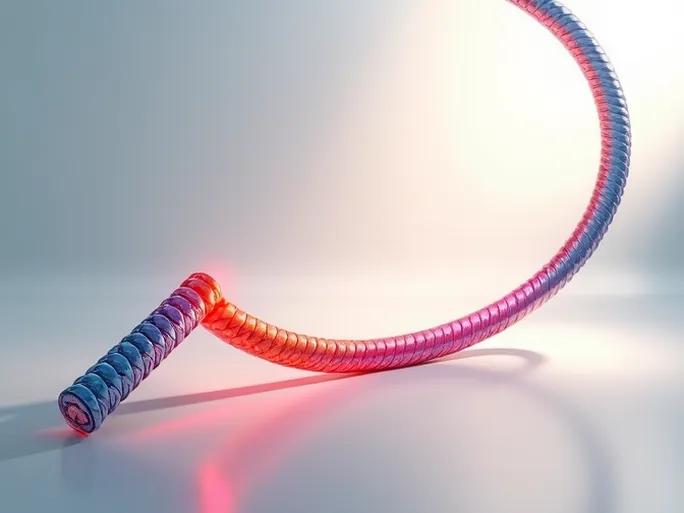

This chain reaction increasingly distorts demand signals as they move upstream, much like how the tip of a bullwhip moves far more dramatically than its handle. The result is severe supply-demand mismatches that erode profitability and competitive advantage.

The Double-Edged Sword of Just-In-Time Manufacturing

The current supply chain crisis reveals the vulnerabilities of just-in-time (JIT) production models. While JIT systems excel at minimizing waste during stable periods by precisely matching supply with demand, they prove fragile when confronted with unexpected shocks.

When suppliers misread demand signals, JIT systems quickly lead to stockouts. Early in the pandemic, many suppliers curtailed production just as consumer demand surged for certain goods. According to the World Trade Organization's Goods Trade Barometer, indices for electronic components (105.1) and raw materials (106.9) far exceeded the 100-point baseline, reflecting both genuine demand spikes for tech products and potential inventory hoarding.

The semiconductor shortage—triggered by booming demand for IoT devices—illustrates this dynamic. While WTO analysts suggest indices may have peaked, with supply chains gradually catching up, another scenario remains possible: as vaccination rates rise, consumer spending might shift back toward services, easing pressure on goods markets.

Strategies for Mitigating the Bullwhip Effect

Companies can implement several measures to counteract supply chain volatility:

1. Optimized Inventory Management: Rather than maintaining expansive product lines, businesses should focus inventory on core offerings. Smaller, more frequent orders and shorter product cycles reduce exposure to demand fluctuations. Streamlining SKUs improves operational efficiency even during normal periods.

2. Strengthened Supplier Relationships: Transparent communication with key suppliers about order forecasts prevents misunderstandings that exacerbate the bullwhip effect. Developing alternative suppliers and transport routes enhances resilience without inadvertently contributing to demand distortion.

3. Enhanced Operational Agility: Empowering procurement teams with real-time, end-to-end supply chain visibility enables faster response to disruptions. Customizable reporting tools help identify vulnerabilities before they escalate.

Building Supply Chain Resilience

The pandemic has underscored that efficiency alone cannot guarantee supply chain stability. Companies must balance lean operations with sufficient flexibility to withstand shocks. This requires:

- Diversified supplier networks to reduce dependency on single sources

- Advanced risk assessment frameworks to anticipate disruptions

- Data-driven inventory optimization to maintain appropriate stock levels

- Collaborative platforms that synchronize information across supply chain partners

As global trade continues facing uncertainty, businesses that successfully tame the bullwhip effect will gain significant competitive advantage. The path forward lies in combining technological solutions with strategic partnerships to create supply chains that are both efficient and resilient.