Behind every online order that arrives at your doorstep lies an unsung hero of modern commerce: the warehouse. While traditional warehouses remain cluttered with shelves and human workers navigating narrow aisles, one company is redefining storage and fulfillment through robotic automation.

The Rise of Grid Storage Systems

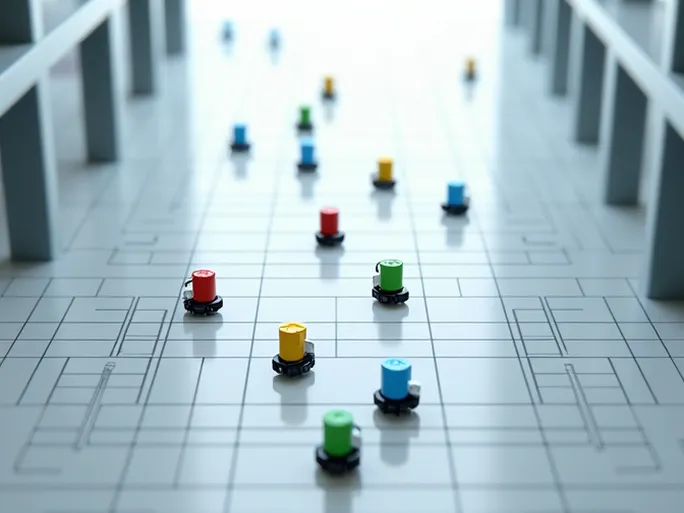

AutoStore, the Norwegian technology company, has pioneered what it calls the "grid storage system" - essentially transforming warehouses into giant three-dimensional chessboards where robots move freely to retrieve items. The company recently announced its 300th North American installation, with healthcare supplier Medline becoming both its first and latest major client in a symbolic full-circle moment.

300+ AutoStore systems now operate across North America

21,000+ robots deployed in these facilities

27 seconds average retrieval time per item

1-4 minutes average processing time for urgent orders

Medline currently operates more than 20 AutoStore systems across the U.S. with 1,900 robots - a veritable mechanical workforce that enables the company to fulfill 95% of customer orders with next-day delivery.

The Need for Speed in the Instant Gratification Era

Modern consumers expect near-instant fulfillment, creating intense pressure on supply chains. AutoStore positions its technology as a high-performance order processing engine that helps businesses meet these escalating demands through:

- Dramatically faster picking speeds

- Near-perfect order accuracy

- Seamlessly scalable infrastructure

The system's performance metrics speak for themselves. With average item retrieval times under 30 seconds and emergency order processing completed within minutes, AutoStore enables businesses to maintain service levels even during demand surges.

Major Brands Bet on Automation

Beyond Medline, AutoStore counts numerous Fortune 500 companies among its clients:

- Ford Motor Company implementing the technology in its automation strategy

- Sonepar and DB Schenker expanding existing deployments

- Early adopters like Best Buy and Puma continuing to rely on the systems

Technological Advancements Driving Growth

AutoStore recently introduced several innovations to maintain its technological edge:

- CarouselAI™ : AI-powered robotic picking solution

- VersaPort™ : Next-generation flexible workstation

- Essentials Software Suite : System optimization tools

These developments complement AutoStore's core grid technology, where robots navigate a dense three-dimensional storage matrix to retrieve inventory bins with unprecedented speed and precision.

Organizational Changes for Enhanced Service

Recognizing that technology alone isn't sufficient, AutoStore has reorganized its Americas operations to provide more integrated customer support. The new structure combines:

- Partner sales

- Solution consulting

- Business development

- Customer success teams

Mike Dickson, recently promoted to President of the Americas, leads this expanded operation. With three decades of automation experience, Dickson emphasizes building future-proof fulfillment systems.

The Future of Automated Warehousing

With over 1,650 systems across nearly 60 countries, AutoStore continues expanding its global footprint while pushing technological boundaries. The company's vision - storing and moving goods efficiently for everyone, everywhere - reflects the growing importance of logistics automation in an increasingly digital economy.

As consumer expectations continue rising and supply chains face new pressures, solutions like AutoStore's robotic systems may well determine which companies thrive in the age of instant gratification.