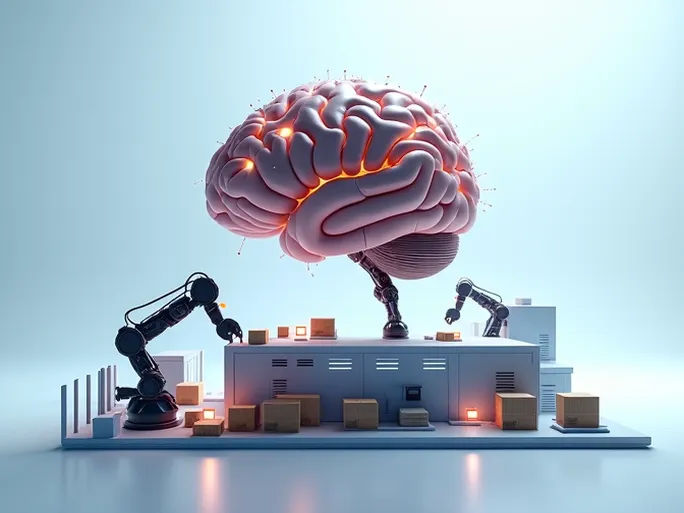

Imagine a warehouse functioning like a highly efficient brain: AI predicts demand with precision, robots swiftly sort goods, and Warehouse Management Systems (WMS) continuously optimize workflows. This is no longer science fiction but an ongoing transformation reshaping global logistics networks.

The logistics sector is undergoing unprecedented change as automation technologies rapidly redefine industry standards. From artificial intelligence-powered software to advanced robotics, these innovations are delivering measurable improvements in operational efficiency, order accuracy, and workforce productivity while addressing persistent labor shortages.

Navigating the Automation Landscape: Balancing Promise and Practicality

While automation presents undeniable opportunities for logistics operations, implementation challenges persist:

- Technology Selection: With numerous solutions available, identifying the optimal fit for specific operational needs remains complex

- System Integration: Ensuring seamless compatibility between new automation technologies and existing infrastructure

- ROI Measurement: Developing reliable frameworks to evaluate automation investments

- Workforce Development: Bridging the skills gap in automation operation and maintenance

Key Areas of Technological Advancement

AI-Driven Optimization: Machine learning algorithms now enable predictive demand forecasting, intelligent inventory management, and dynamic resource allocation. Advanced applications include route optimization, personalized customer service interfaces, and real-time exception management.

Robotic Process Automation: Autonomous Mobile Robots (AMRs), Automated Guided Vehicles (AGVs), and sophisticated picking systems are transforming warehouse operations. These solutions demonstrate particular effectiveness in high-volume picking operations, precision packaging, and heavy material handling.

Next-Generation WMS: Modern warehouse management systems serve as the central nervous system for automated facilities, integrating with robotics and AI platforms while providing comprehensive inventory visibility, order tracking, and performance analytics.

Data as the Differentiator

The most successful implementations combine physical automation with advanced data analytics. Real-time monitoring dashboards, predictive maintenance algorithms, and continuous process improvement systems are becoming standard features in leading logistics operations.

As the industry continues its automation journey, organizations must balance technological adoption with workforce development strategies. The transition requires both technical upskilling and organizational restructuring to maximize the potential of these transformative technologies.