In the rapidly evolving logistics and warehousing industry, storage racks have become essential tools for improving storage efficiency and space utilization. Whether heavy-duty or medium-duty, each type of storage rack offers unique advantages tailored to specific scenarios. Selecting the appropriate rack system is not only crucial for ensuring the safety of stored goods but also plays a pivotal role in enhancing overall operational efficiency. This article explores the key differences and ideal applications of heavy-duty and medium-duty storage racks to help businesses make informed decisions.

I. Basic Definitions of Storage Racks

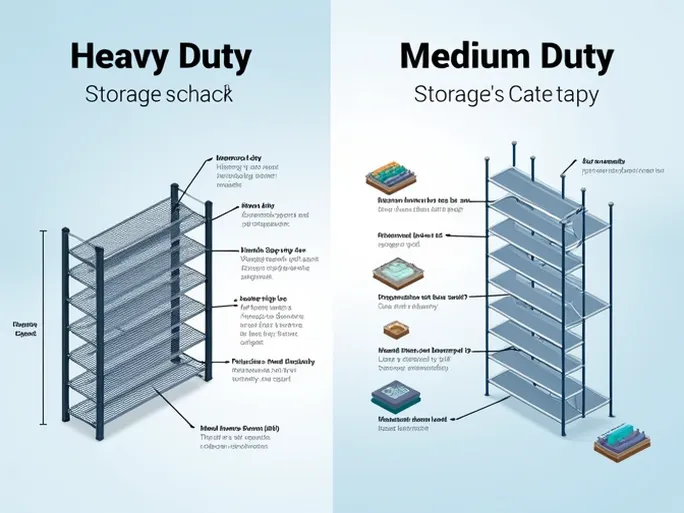

Storage racks, as the name suggests, are structures designed to hold and organize stored items. Based on storage requirements, load capacity, and available space, racks are categorized into various types. Among these, heavy-duty and medium-duty storage racks are the most common in industrial and commercial warehouses, each serving distinct storage needs through their load-bearing capacities and design features.

1. Heavy-Duty Storage Racks

Heavy-duty storage racks are typically used in industries such as machinery manufacturing, automotive, and chemical production, where superior load-bearing capacity and structural stability are paramount. Constructed from high-strength steel, these racks are durable and robust, capable of supporting several tons of weight per level. With a maximum load capacity of up to 4 tons per shelf and heights reaching 10 meters, heavy-duty racks are ideal for high-density storage in large warehouses, maximizing vertical space utilization.

Ideal Applications: Heavy-duty racks are suited for storing large, bulky, or heavy items. For instance, in the automotive sector, they efficiently manage heavy components and equipment. Similarly, in manufacturing facilities, these racks are used to store bulk raw materials, enabling centralized inventory management and optimal space utilization.

2. Medium-Duty Storage Racks

Medium-duty storage racks offer greater flexibility and ease of use, often featuring modular, bolt-free designs that simplify assembly and disassembly. These racks are commonly found in small warehouses, retail stores, and distribution centers. With a typical load capacity of around 500 kg per shelf, medium-duty racks are less robust than their heavy-duty counterparts but excel in handling diverse storage needs. Their adjustable shelf heights (usually in 75 mm increments) facilitate efficient organization and quick access to goods.

Ideal Applications: Medium-duty racks are well-suited for industries such as electronics, food, and pharmaceuticals, particularly in retail environments with high inventory turnover. They streamline restocking and inventory checks, reducing operational time and boosting efficiency.

II. Key Differences Between Heavy-Duty and Medium-Duty Racks

While both rack types serve distinct purposes, they differ significantly in the following aspects:

1. Structure and Load Capacity

Heavy-duty racks are built for stability and can withstand substantial weights, whereas medium-duty racks prioritize flexibility and lighter loads. Heavy-duty racks typically support over 4 tons per shelf, while medium-duty racks handle approximately 500 kg.

2. Ease of Installation and Adjustability

Medium-duty racks are easier to assemble and reconfigure, allowing for quick adjustments to shelf spacing. Heavy-duty racks, however, often require professional installation due to their complex, heavy-duty construction.

3. Space Utilization

Heavy-duty racks excel in vertical storage, making them ideal for high-ceiling warehouses. Medium-duty racks, on the other hand, are better suited for lower-height storage with frequent access needs.

4. Industry Applications

Heavy-duty racks are predominantly used in industrial sectors like automotive and chemicals, while medium-duty racks are favored in retail, logistics, and light manufacturing.

III. Safety and Usage Guidelines

Safety is critical when using either type of storage rack. Adhering to best practices can prevent accidents and prolong rack lifespan:

- Load Limits: Never exceed the weight capacity per shelf, and ensure even weight distribution.

- Item Size: Store goods that fit within the rack's dimensions to prevent instability.

- Operator Care: Avoid forklift collisions with racks and use standardized pallets for balanced loads.

- Worker Safety: Minimize time spent beneath loaded shelves to reduce injury risks from falling items.

IV. Choosing Between Heavy-Duty and Medium-Duty Racks

Selecting the right rack system depends on several factors:

- Goods Type: Heavy items necessitate heavy-duty racks, while lighter, fast-moving goods are better suited to medium-duty systems.

- Warehouse Space: Consider ceiling height and floor area. High ceilings favor heavy-duty racks, while lower spaces benefit from medium-duty configurations.

- Operational Flexibility: Frequent access demands may favor medium-duty racks, whereas static, high-volume storage aligns with heavy-duty solutions.

V. Conclusion

Heavy-duty and medium-duty storage racks each offer distinct advantages tailored to specific operational needs. By evaluating factors such as inventory type, space constraints, and workflow requirements, businesses can optimize warehouse efficiency and safety. Effective rack selection not only enhances storage capacity but also strengthens overall logistics performance, making it a critical consideration in modern supply chain management.