The logistics industry is undergoing unprecedented transformation in today's rapidly evolving business environment. The explosive growth of e-commerce, increasing consumer demand for faster delivery, and the complexity of global supply chains are posing significant challenges to traditional logistics models.

The Transformation Wave: Embracing Next-Gen Distribution Centers

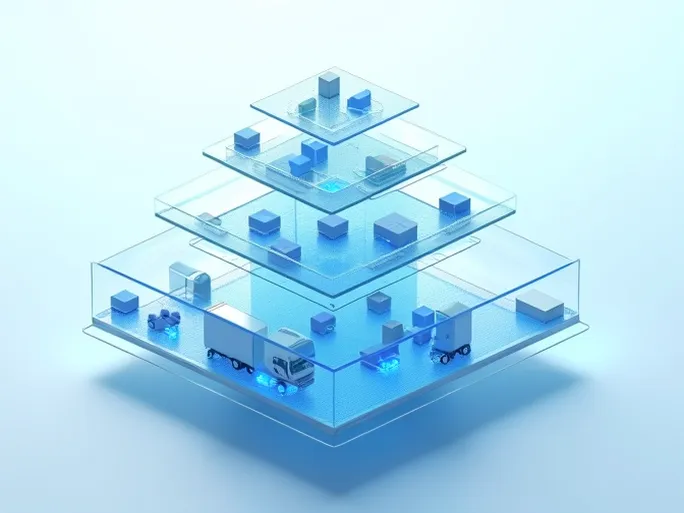

Next-generation logistics distribution centers represent the core of this transformation. These are not simply warehouses, but highly integrated intelligent networks that combine automation, multi-tier networks and data-driven decision making to achieve faster, more accurate order fulfillment that meets evolving market demands.

1. Automation Upgrade: The Core Engine of Order Fulfillment

Automation is an inevitable trend in the development of future logistics distribution centers. While major retailers and logistics companies have already automated certain processes, challenges remain—particularly when handling irregularly shaped or non-standard packaged goods.

Current robotic and automation technologies excel at processing standard-sized, regularly shaped packages but require additional human intervention for irregular items. While machines still need time to learn how to handle non-standard packaging, mature automated solutions already exist for lightweight, regularly shaped goods.

Key Advantages of Automation:

- Enhanced efficiency: Automated systems can operate 24/7, significantly improving order processing speed and throughput.

- Cost reduction: Minimized human intervention lowers labor costs and reduces losses from human error.

- Resource optimization: Automated systems enable more efficient use of warehouse space and equipment.

Automation Applications:

- Automated Guided Vehicles (AGVs): Driverless vehicles that transport goods autonomously within warehouses.

- Automated Storage and Retrieval Systems (AS/RS): Systems that automatically store and retrieve goods.

- Robotic Sorting Systems: Systems that automatically identify and sort items.

- Automatic Carton Sealers: Machines that automate box folding and sealing.

2. Multi-Tier Networks: Building Agile Supply Chains

Traditional single-tier distribution networks can no longer meet growing customer demands. To maintain competitiveness in both speed and pricing, future logistics centers will adopt multi-tier network structures.

The Four-Tier Network Structure:

- Large Distribution Centers (LDC): Located in suburban or low-cost areas, primarily storing bulk, long-tail items.

- Cross-Docking Centers: Smaller facilities focused on rapid unloading, transfer and reloading.

- Regional Distribution Centers (RDC): Medium-sized facilities storing pallet and case goods.

- Forward Distribution Fulfillment Centers (FDFC): Small urban facilities located close to consumers.

3. Data-Driven Operations: The Foundation of Lean Management

In highly automated multi-tier networks, accurate forecasting is essential. Only through precise predictions of market demand, inventory status and transportation capacity can goods arrive at the right place at the right time in the right quantities.

Inventory management, demand forecasting and stock placement represent critical challenges. Reliable data analytics enable companies to predict product sales based on historical data and market trends, then adjust inventory and distribution strategies accordingly.

4. The Unmanned Trend: Entering the "Dark Warehouse" Era

With continuous advances in automation, some logistics centers have achieved fully unmanned operations. These "dark warehouses" primarily handle regularly shaped goods with minimal human intervention.

As technology matures, more facilities will transition to unmanned operations where automation handles repetitive tasks while human employees focus on creative and strategic work.

5. Human-Machine Collaboration: Creating Efficient Synergy

Despite automation trends, human workers remain essential in logistics centers. The future challenge lies in effectively combining human employees with automated equipment to create highly efficient operational models.

Human workers excel at complex, non-standardized tasks while automation handles repetitive functions. By combining these strengths, companies can significantly improve overall operational efficiency.

Conclusion

Future logistics distribution centers will become highly automated, data-driven, multi-tier intelligent networks. Companies must actively embrace new technologies and models to optimize supply chain management and maintain competitive advantage.

Looking ahead, emerging technologies like blockchain, 3D printing, augmented reality and virtual reality will further transform logistics operations while sustainability considerations will drive greener solutions.