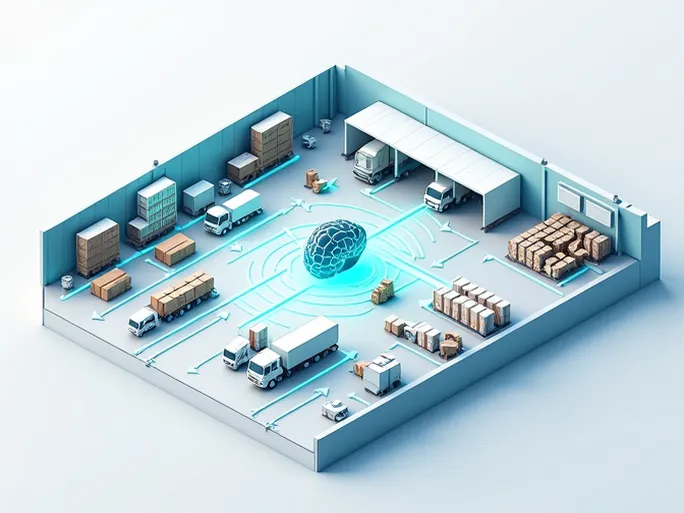

Imagine a bustling logistics yard where countless trucks move seamlessly, operations run with clockwork precision, and efficiency reaches unprecedented levels. This vision is becoming reality through the partnership between Ryder System Inc. and Terminal Industries, as artificial intelligence takes center stage in warehouse management.

Pilot Programs Demonstrate Remarkable Accuracy

The Miami-based logistics leader and the AI platform developer launched their first pilot program in January at Ryder's e-commerce fulfillment center in City of Industry, California. Terminal Industries' computer vision technology served as "digital eyes," precisely tracking truck movements with 99% accuracy in identifying license plates and Department of Transportation numbers across more than 10,000 truck detections.

A second pilot launched in July at Ryder's truck rental and maintenance center in the Dallas-Fort Worth area expanded the technology's applications to inventory management. Using mobile tablets, the system automatically captured real-time stock information, demonstrating AI's versatility in warehouse operations.

Machine Learning Drives Continuous Improvement

Terminal's solution combines computer vision with machine learning algorithms that progressively enhance recognition accuracy. The system integrates with third-party databases to build comprehensive vehicle profiles beyond what cameras can capture.

"Yards are critical nodes in end-to-end supply chains," explained Terminal CEO Max Constant. "Our technology represents a core solution adaptable to multiple scenarios, not just point-specific applications."

Constant illustrated this flexibility: "In California, we track moving vehicles entering Ryder facilities. In Dallas-Fort Worth, we use the same core technology with mobile tablets to record stationary trucks. We're currently developing two additional pilots to explore further applications."

Cost-Effective Implementation Accelerates Adoption

Unlike systems requiring specialized hardware, Terminal's solution works with existing security cameras and off-the-shelf devices. Cloud connectivity enables data processing without costly infrastructure upgrades, significantly reducing implementation barriers.

The technology uses ordinary cameras and tablets to automatically identify and index trucks, trailers, chassis, and containers while continuously refining its understanding of warehouse environments through machine learning.

From Pilot to Production: The Road Ahead

With the initial pilot's success, Ryder plans to transition the technology into commercial production. Placensia emphasized moving beyond testing phases to full-scale implementation, reflecting confidence in AI's potential to transform logistics operations.

This collaboration represents more than technological adoption—it signals a strategic shift as traditional logistics providers embrace digital transformation. The partnership promises operational efficiencies, better resource allocation, enhanced customer experiences, and industry leadership in innovation.

As AI capabilities mature, future applications could include intelligent scheduling based on real-time traffic, predictive maintenance through equipment monitoring, and advanced security systems—ushering in a new era of smart logistics.