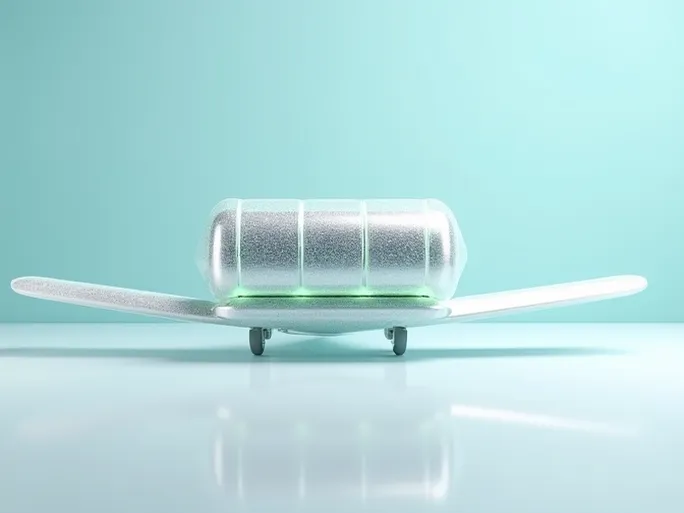

Imagine a power battery stranded at an airport due to non-compliance with air transport standards, causing not just economic losses but potential safety hazards. As the new energy industry flourishes, air transport standards for its core product—batteries—are undergoing continuous upgrades, presenting higher demands for the logistics sector. Air freight services now face systemic transformation, centered on enhancing safety measures and implementing comprehensive carbon management throughout the product lifecycle, directly impacting logistics providers' certification systems and operational procedures.

Upgraded Certification Standards: Balancing Safety and Compliance

The core changes in air transport standards for new energy products involve expanded battery classifications and refined safety thresholds, specifically manifesting in these aspects:

- Expanded battery types: New UN numbers now cover sodium-ion batteries, addressing regulatory gaps for emerging energy products. Logistics providers must update declaration systems and labeling protocols to meet these updated requirements.

- Stricter state-of-charge controls: State-of-charge (SOC) management has evolved from recommended guidelines to mandatory constraints in certain scenarios. For instance, some situations now require battery charge levels below 30% to mitigate thermal runaway risks, necessitating specialized discharge procedures during transport.

- Enhanced packaging tests: New 3-meter stacking requirements for packaging strength verification compel companies to optimize cushioning materials and structural designs, preventing battery damage from external pressure during transit.

Businesses requiring air freight services should closely monitor surcharge policies and adjust transport plans considering certification costs, avoiding budget overruns from sudden regulatory changes. Comparison platforms become particularly valuable here, enabling cost evaluations across different routes for optimal decision-making.

Supply Chain Coordination and Compliance Innovation

Meeting these upgraded standards requires restructuring the entire "testing-declaration-transport" workflow:

- Testing phase: Laboratories must now accommodate dual requirements for sodium-ion battery humidity tests and lithium battery carbon footprint reports, driving capacity expansions to handle increased testing demands.

- Customs clearance: Enhanced data transparency becomes crucial. Pre-declaration systems must integrate UN numbers, SOC levels, and packaging certification codes to prevent documentation conflicts that might cause inspection delays.

- Transport operations: Dynamic routing strategies become essential. High-energy-density batteries should prioritize direct flights to minimize transfers, while temperature-sensitive shipments require climate-controlled cargo space with real-time temperature monitoring accessible to regulators.

Standardization and Digital Integration: Key Adaptation Strategies

The certification upgrades fundamentally represent progress in both safety and environmental protection. Companies must respond through:

- Standardized operational protocols: Ensuring all processes comply with updated regulations to minimize human errors.

- Digital collaboration: Implementing information technology for real-time data sharing and monitoring to enhance both efficiency and safety.

These regulatory changes in new energy air transport present both challenges and opportunities. Proactive adaptation remains crucial for success in this evolving logistics landscape.