In the fast-paced world of modern logistics, pallets have become the unsung heroes of global commerce. These seemingly simple platforms serve as the fundamental building blocks for transporting and storing goods, quietly revolutionizing how products move from manufacturers to consumers. As e-commerce continues its explosive growth and supply chain management evolves, the strategic selection of pallet types—particularly the shift toward 4-way pallets—has emerged as a critical factor in operational efficiency.

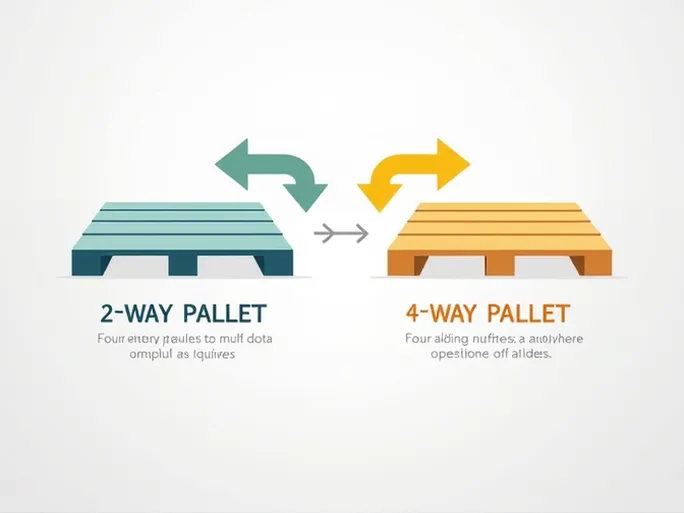

A recent industry discussion sparked by a procurement requirement—"All Cargo Must be on 4-Way Pallet"—has brought this often-overlooked logistics component into sharp focus. This specification highlights a crucial distinction between the two primary pallet types: 2-way and 4-way pallets. Understanding this difference can significantly impact warehouse productivity, transportation efficiency, and ultimately, a company's bottom line.

The Fundamental Difference: Access Points Matter

At their core, pallets serve one primary function: to facilitate the movement of goods by forklifts and pallet jacks. Their design aims to streamline loading, storage, and distribution processes. However, the direction from which forklifts can access these platforms creates the critical distinction between the two main types.

2-Way Pallets , as the name suggests, only allow forklift access from two opposite sides. This limitation can create operational bottlenecks, particularly in confined warehouse spaces where maneuvering room is limited. While some 2-way pallet designs offer higher weight capacities and often feature more robust construction, their inherent lack of flexibility frequently outweighs these advantages in modern logistics environments.

In contrast, 4-Way Pallets offer superior operational flexibility by permitting forklift access from all four sides. This design innovation dramatically improves loading and unloading efficiency, allowing warehouse personnel to approach pallets from any direction. The practical benefits become especially apparent in high-volume distribution centers where every second of loading time translates to significant cost savings.

The Efficiency Revolution in Modern Warehousing

As supply chain velocity becomes increasingly crucial to competitive advantage, more companies are mandating the exclusive use of 4-way pallets in their operations. The reasons for this shift are compelling: 4-way pallets can reduce loading times by up to 30% in certain applications, while simultaneously decreasing product damage from awkward loading angles.

The financial implications of this transition are equally significant. While 2-way pallets might appear more economical in initial procurement costs, the long-term operational efficiencies of 4-way pallets often deliver substantially better total cost of ownership. Forward-thinking logistics managers now factor in these hidden productivity gains when evaluating pallet options.

Beyond Access: Material Innovation and Smart Technology

The pallet evolution extends beyond just entry points. Today's market offers various materials—from traditional wood to durable plastics and metals—each with distinct advantages. Wood remains popular for its cost-effectiveness and recyclability, while plastic gains market share through its durability and hygienic properties, particularly in food and pharmaceutical applications.

Perhaps most exciting is the emergence of smart pallet technology. Innovative solutions incorporating RFID tracking and IoT connectivity are transforming pallets from passive platforms into intelligent nodes within the supply chain network. These advancements enable real-time inventory tracking, temperature monitoring, and even predictive analytics for maintenance scheduling.

As logistics operations continue their relentless pursuit of efficiency, the humble pallet has proven to be anything but ordinary. The industry's growing preference for 4-way designs reflects a deeper understanding of how foundational elements can drive systemic improvements. In an era where supply chain resilience makes or breaks businesses, optimizing even the most basic components—like pallet selection—can deliver outsized competitive advantages.