In today's increasingly frequent global trade, export has become crucial for business development. However, product quality and compliance remain paramount in this process. Commodity inspection, as an essential part of foreign trade export procedures, plays a vital role in ensuring products meet the regulations, standards, and requirements of importing countries. Yet not all goods require inspection, making it necessary for exporters to understand the relevant processes and conditions.

Understanding HS Codes and Inspection Requirements

Each export product corresponds to a specific Harmonized System (HS) code. This classification not only identifies the product category but also serves as the foundation for understanding regulatory conditions and application requirements. By checking the relevant HS code, exporters can clearly determine whether their product requires inspection and what regulations apply.

The basic inspection requirements fall into these categories:

- None: No mandatory inspection required; exporters may proceed directly with export

- A: Inspection only required upon import; no need for export inspection

- B: Mandatory inspection required before export to ensure customs clearance

- AB: Inspection required both for export and import, increasing time and cost requirements

It's important to note that common products requiring inspection typically include food, plants, and pharmaceuticals. Due to stringent regulatory standards in these sectors, exporters must maintain strict control over product compliance.

The most direct way to determine inspection requirements is by checking the product's HS code on relevant customs websites. Consulting experienced freight forwarders can also provide valuable guidance. A common misconception involves the 2015 Dangerous Chemicals Catalog — while it serves as a reference, not all listed hazardous materials necessarily require inspection.

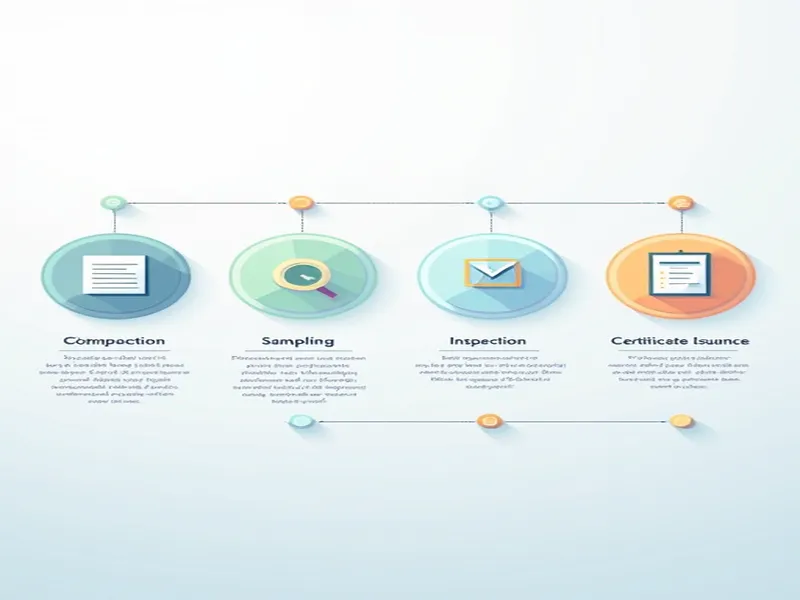

The Commodity Inspection Process

When inspection is confirmed necessary, exporters must follow these critical steps:

1. Application Acceptance: The applicant must complete an "Export Inspection Application" and submit it along with relevant documents including the foreign trade contract, letter of credit, and factory inspection results. The inspection authority will review all materials for compliance before acceptance. Any deficiencies require immediate correction to proceed.

2. Sampling: After acceptance, inspectors will randomly select samples from the shipment. Exporters must fully cooperate during this process to demonstrate product authenticity and compliance. Proper sampling methods ensure inspection fairness and transparency.

3. Inspection: The core phase involves comprehensive technical examination according to relevant standards. This may include sensory checks (appearance, smell) as well as chemical and instrumental analysis. Inspection methods may vary, including self-inspection, joint inspection, factory inspection, or origin inspection. Accuracy here determines successful customs clearance.

4. Certificate Issuance: For compliant products, the inspection authority issues a certificate and stamps the "Export Customs Declaration Form" with a release seal. This certificate serves as proof of compliance and is essential for customs declaration. Exporters must complete the process within the validity period to avoid financial losses.

Required Documentation

Proper documentation is essential for smooth inspection processing:

- Foreign trade contract detailing product specifications and terms

- Letter of credit establishing trade trust

- Any supplementary agreements to the contract

- Updated documents if information changes

- For specific products, packaging performance qualification certificates may be required

Understanding inspection processes and requirements gives exporters a competitive advantage in compliance. By staying informed about regulatory changes and maintaining open communication with authorities, businesses can strengthen their global operations. Rigorous inspection procedures not ensure smooth customs clearance and product compliance but also build consumer trust in competitive markets. With thorough preparation and careful execution, exporters can establish outstanding brand reputations in international markets.