In the rapidly growing logistics industry, pallet standardization has emerged as a crucial factor for improving transportation efficiency and reducing costs. As an indispensable component of modern logistics, pallets play an increasingly prominent role in cargo handling, transportation, and warehousing. However, the promotion of pallet standardization faces numerous challenges and obstacles that hinder its widespread adoption. This article explores the importance of pallet standardization, the practical difficulties in its implementation, and proposes strategies to overcome these challenges.

1. The Importance of Pallet Standardization

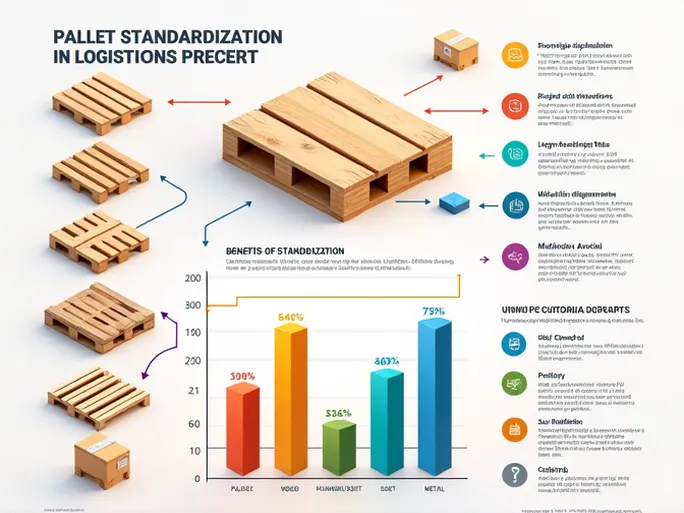

As fundamental infrastructure in logistics operations, standardized pallets significantly enhance efficiency and safety. Standardization reduces cargo damage caused by improper packaging and loading while optimizing space utilization in storage and transportation. Moreover, it facilitates digital transformation in logistics enterprises by enabling information technology applications in pallet management, thereby reducing labor costs and improving operational efficiency.

1.1 Reducing Social Logistics Costs

Pallet standardization is widely recognized as an effective approach to lowering overall logistics costs. Uniform standards help eliminate inefficiencies in loading and unloading caused by inconsistent pallet specifications, thereby improving cargo flow. Standardized pallets also promote resource sharing and recycling, ultimately reducing operational costs. Data shows that standardized pallets account for only 23% of the domestic market share, with a mere 2% recycling rate—significantly lower than the 40-50% levels in developed countries.

1.2 Supporting Automation and Smart Logistics

With rapid technological advancement, automation and intelligence have become inevitable trends in logistics. Standardized pallets provide necessary compatibility conditions for automated equipment such as automated storage systems, conveyor lines, and sorting systems, enabling efficient and precise operations. Additionally, standardized pallets facilitate digital management systems, allowing enterprises to track and monitor pallets using RFID and other information technologies to enhance operational efficiency.

2. Current Status and Challenges of Pallet Standardization

Despite its evident benefits, pallet standardization faces several obstacles in implementation. The market suffers from a proliferation of pallet specifications and inconsistent quality, creating significant challenges for enterprises.

2.1 Market Fragmentation Needs Addressing

Domestic enterprises commonly use pallets of varying quality and dimensions in logistics transportation, making recycling difficult. The market primarily features two international standard pallet sizes (1.2m×1m and 1.1m×1.1m), which don't suit all industries. For instance, the automotive industry's parts transportation requirements often don't align with these standard pallets, forcing companies to develop customized solutions that increase costs and resource waste. This market diversity creates operational inefficiencies, highlighting the urgent need for market regulation and consolidation.

2.2 Lack of Enterprise Motivation

While pallet standardization offers clear social benefits by reducing resource waste, many enterprises lack internal motivation to drive this initiative. The primary challenge lies in the market's inconsistent pallet quality and absence of unified standards, requiring companies to bear additional costs—particularly production line adjustments—that disrupt normal operations. Consequently, enterprises often prioritize short-term cost considerations over standardization efforts.

2.3 Lagging Industry Standardization

The promotion of pallet standardization faces compatibility issues across industries. For example, inconsistent standardization progress in shelving, warehouses, and transportation tools leads to poor inter-industry coordination. Different sectors—such as steel, electronics, and cold chain logistics—have varying pallet requirements, making cross-industry communication and collaboration essential for achieving harmonious development.

2.4 Unfavorable Implementation Environment

The current environment doesn't sufficiently support pallet standardization. Most enterprises treat pallets as fixed assets, making the high replacement costs of new standardized pallets a significant deterrent. The lack of clear policy support further exacerbates enterprise concerns, preventing the establishment of long-term mechanisms for rapid standardization progress.

3. Strategies to Promote Pallet Standardization

To overcome current bottlenecks and enhance pallet utilization efficiency, effective measures must be implemented to advance logistics industry development.

3.1 Establish a Nationwide Unified Standardization Plan

First, develop a comprehensive national pallet standardization plan addressing industry-specific needs in size, material, and load capacity. Strengthen enforcement through legislation and policy to ensure corporate compliance in pallet procurement and usage. Government should guide industry self-regulation by establishing pallet standardization working groups to regularly assess standards' applicability and effectiveness, ensuring market stability.

3.2 Strengthen Policy Implementation and Subsidies

Governments should complement standardization plans with supportive policies and subsidies to highlight long-term benefits. Financial incentives and tax reductions can alleviate short-term cost pressures, increasing enterprise participation. Pilot programs across industries can generate successful cases for broader reference.

3.3 Promote Enterprise Collaboration and Resource Sharing

Forming cross-industry and regional logistics alliances is crucial for pallet standardization. Shared resources and unified standards enable more convenient pallet usage among enterprises. Cooperative approaches like pallet pooling and information platform development can reduce operational costs while improving utilization and circulation efficiency. Industry alliances can also expand standardization's influence through external promotion.

3.4 Drive Enterprise Innovation and Transformation

Enterprises should actively explore new models integrating logistics with information technology during standardization. Implementing information management systems and pallet tracking can enhance lifecycle management and intelligent operations. Innovation in pallet materials and design—such as lightweight, eco-friendly solutions—can meet diverse market needs while maintaining standardization.

3.5 Enhance Training and Awareness

Specialized training sessions and enterprise exchanges can raise awareness about pallet standardization's importance. Industry experts can share practical experiences to facilitate effective implementation. Increased understanding and recognition will drive standardization efforts forward.

4. Future Outlook

Promoting pallet standardization is essential for improving China's logistics efficiency and reducing social resource waste. Standardization requires practical action through strengthened policies, industry standards, and enterprise collaboration, laying a solid foundation for logistics industry development.

Amid global logistics integration, standardized pallets will not only modernize China's logistics sector but also enhance its international competitiveness. As logistics technology advances, pallet standardization's prospects will broaden, requiring collective industry efforts to accelerate progress and ensure sustainable development.

This analysis aims to draw attention from enterprises and research institutions, encouraging greater contributions to China's pallet standardization. Recognizing its significance and implementing practical measures will boost logistics efficiency while supporting economic development.