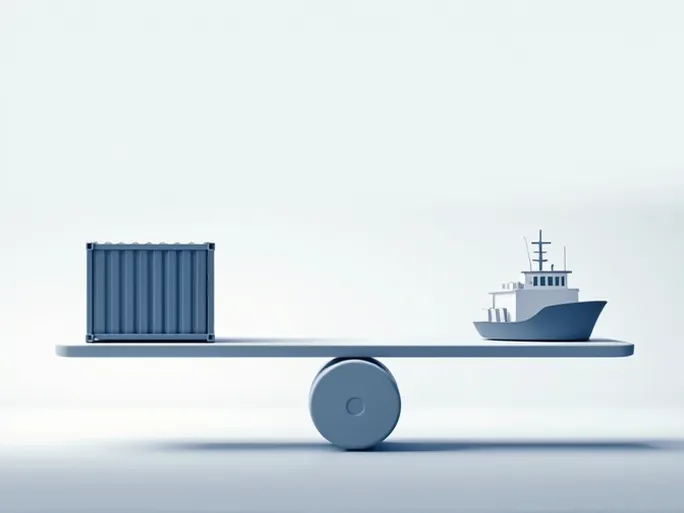

When cargo shipments face congestion, the question arises: Should loaded containers be temporarily stored at freight depots or left stacked at backed-up ports? This decision is not merely about space—it impacts costs, efficiency, and the smooth operation of supply chains. Industry experts emphasize that selecting the right storage location can prevent unnecessary losses and optimize logistics processes.

In most cases, choosing to store containers at freight depots rather than ports or yards is driven by several key factors. For manufacturers, depots provide short-term warehousing space, alleviating pressure on factory storage—particularly during peak production periods or when space is limited. When ports experience congestion, relocating containers to depots helps avoid additional demurrage fees and reduces waiting times. Depots also serve as secure temporary storage for goods in transit or awaiting customs clearance.

Freight depots typically offer lower storage costs compared to ports, making them a cost-effective solution for longer-term storage needs. Additionally, depots can break down full truckloads into smaller, more manageable shipments, facilitating subsequent distribution and improving overall logistics efficiency.

Considering factors such as cost, space utilization, operational efficiency, and compliance, storing containers at freight depots often proves to be the more advantageous strategy. Companies should assess their specific needs and weigh the trade-offs to make informed decisions that ensure stable and efficient supply chain operations.