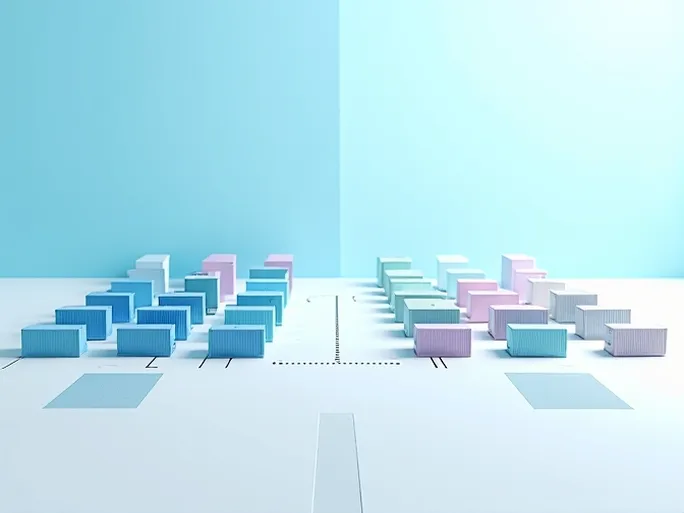

In the vast landscape of global trade, container shipping plays a pivotal role. However, many businesses find themselves perplexed by the frequent technical terms encountered in container logistics, particularly CY (Container Yard) and CFS (Container Freight Station). These seemingly simple abbreviations actually represent two fundamental nodes in the supply chain that directly impact transportation efficiency, cost control, and the overall success of logistics strategies. This article provides an in-depth analysis of CY and CFS concepts, functions, differences, and their applications across various logistics models.

CY (Container Yard): The Temporary Hub for Containers

A Container Yard (CY) is a designated area within ports or terminals primarily used for temporary container storage and management. Functioning as a "parking lot" for containers, it serves as the holding area where containers await loading onto vessels or collection after being unloaded. CYs typically feature specialized lifting equipment and management systems to ensure secure, organized storage and efficient operations.

Key Functions of CY:

- Container Storage: Provides temporary space for containers to meet post-discharge storage needs and pre-loading consolidation requirements.

- Container Management: Registers, stacks, maintains, and tracks all containers moving through the facility to ensure accurate documentation and traceability.

- Container Handover: Facilitates container transfers between shipping lines, freight forwarders, and trucking companies to ensure secure movement.

Characteristics of CY:

- Location: Positioned within port or terminal areas near berths for quick container handling.

- Primary Users: Serves shipping lines, freight forwarders, and clients with full container loads (FCL).

- Operations: Involves straightforward processes limited to container movements and storage without cargo handling.

CFS (Container Freight Station): The Cargo Consolidation Center

A Container Freight Station (CFS) refers to warehouse facilities located near ports or inland areas that specialize in less-than-container-load (LCL) cargo consolidation, distribution, and container stuffing/stripping operations. Functioning as cargo "transshipment hubs," these facilities aggregate shipments from multiple shippers into containers or deconsolidate containerized cargo for final delivery.

Key Functions of CFS:

- LCL Consolidation: Receives and manages fragmented shipments from multiple shippers.

- Cargo Distribution: Sorts inbound containerized cargo by destination or consignee.

- Container Stuffing/Stripping: Consolidates loose cargo into FCL or breaks down containers into individual shipments.

- Cargo Tallying: Verifies, marks, and categorizes all incoming/outgoing goods.

- Customs Processing: Provides customs clearance and inspection support.

- Storage Services: Offers short-term or long-term warehousing solutions.

Characteristics of CFS:

- Location: Strategically positioned near ports or inland with strong transportation links.

- Primary Users: Serves freight forwarders, NVOCCs, and LCL shippers.

- Operations: Involves complex processes including cargo receipt, sorting, container handling, and customs procedures.

CY vs. CFS: Comparative Analysis

| Feature | Container Yard (CY) | Container Freight Station (CFS) |

|---|---|---|

| Primary Function | Container storage and management | Cargo consolidation, stuffing/stripping, customs processing |

| Location | Within ports/terminals | Near ports or inland areas |

| Primary Users | Shipping lines, forwarders, FCL clients | Forwarders, consolidators, LCL clients |

| Cargo Type | FCL (Full Container Load) | LCL (Less than Container Load) |

| Operations Complexity | Simple container handling | Complex cargo handling processes |

| Responsible Party | Shipping lines or terminal operators | Forwarders or CFS operators |

| Cost Components | Storage fees, handling charges | Consolidation fees, customs charges |

Logistics Models: CY/CY, CY/CFS, and CFS/CFS Applications

International trade utilizes different container movement models based on origin, destination, and shipment characteristics, each with distinct cost and efficiency implications.

1. CY/CY Model: Door-to-Door FCL Movement

- Definition: Containers move from origin CY to destination CY without intermediate handling.

- Application: Suitable for FCL shipments where both parties can handle container stuffing/stripping.

- Advantages: Streamlined process, cost-effective.

- Limitations: Requires container handling capabilities at both ends.

2. CY/CFS Model: FCL with Destination Breakdown

- Definition: Containers move from origin CY to destination CFS for deconsolidation.

- Application: Ideal for FCL shipments requiring multi-party distribution at destination.

- Advantages: Enables multi-consignee distribution.

- Limitations: Additional handling costs and time at destination.

3. CFS/CFS Model: LCL Consolidation and Distribution

- Definition: Cargo moves through consolidation at origin CFS and deconsolidation at destination CFS.

- Application: Designed for LCL shipments without full container requirements.

- Advantages: Economical for small shipments.

- Limitations: Longer transit times, increased handling risks.

The strategic selection between CY and CFS operations significantly influences supply chain efficiency and cost structures in international trade. Businesses that properly understand these container logistics components can optimize their shipping strategies and enhance global trade competitiveness.