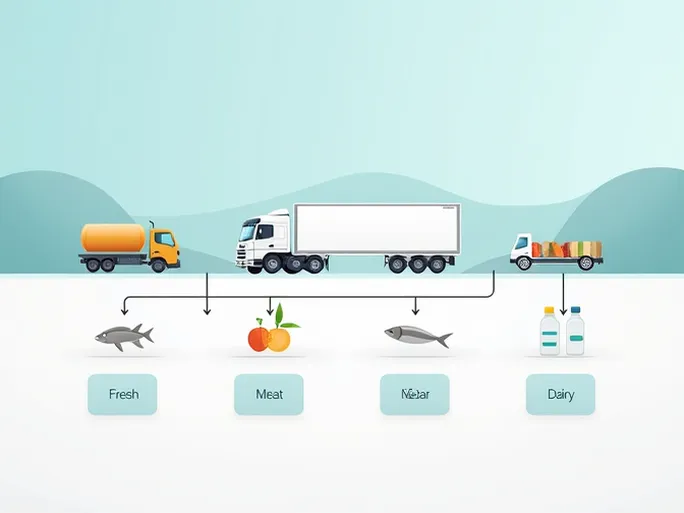

Refrigerated containers, commonly known as reefer containers, are the unsung heroes of global commerce. These specialized units maintain optimal climate conditions during transportation, ensuring perishable goods arrive at their destinations fresh and safe for consumption. But what exactly do these high-tech containers transport, and how do they safeguard the quality of our daily food and essential goods?

Engineering Marvel: The Design and Capabilities of Reefer Containers

Reefer containers are far more sophisticated than standard shipping units. Engineered with advanced technology, they feature insulated walls constructed from rust-resistant materials to withstand diverse weather conditions. At their core lies a powerful refrigeration system capable of rapid cooling and precise temperature maintenance.

These containers operate across an impressive temperature spectrum, ranging from -30°C to +30°C (-22°F to 86°F). Advanced control systems allow operators to fine-tune both temperature and humidity levels to match specific cargo requirements. While tropical fruits might need warmer transport conditions, frozen products like ice cream demand sub-zero environments as cold as -20°C (-4°F). This remarkable flexibility makes reefer containers indispensable for modern supply chains.

Preserving Nature's Bounty: Fresh Produce Transportation

The global fresh produce market relies heavily on reefer technology. These containers simulate ideal storage conditions for various fruits and vegetables, effectively slowing the ripening process. Different produce items have distinct temperature needs - bananas thrive at 12-14°C (54-57°F), while delicate berries require colder conditions to maintain texture and flavor.

Post-harvest deterioration presents a significant challenge. Once picked, fruits and vegetables immediately begin oxidizing, with bacteria and mold proliferating rapidly when exposed to air and moisture. Reefer containers combat this natural process through continuous cooling and humidity control. The effectiveness of this cold chain directly impacts shelf life at retail destinations, making it critical for supply chain success.

Meat and Seafood: Overcoming Transportation Challenges

Maintaining food safety standards during meat and seafood transport presents unique difficulties. Reefer containers address these challenges by creating low-temperature environments that inhibit bacterial growth. Preventing thaw cycles is particularly crucial, as repeated freezing and thawing can dramatically reduce product quality.

Meat typically requires temperatures between 0°C and 4°C (32-39°F), while seafood maintains optimal freshness between -1°C and 2°C (30-36°F). Humidity control proves equally important for seafood, as excessive moisture loss can degrade texture and flavor. Many shippers now employ vacuum packaging and other advanced techniques to enhance product stability during transit.

The Dairy Supply Chain: From Farm to Consumer

Milk, cheese, and other dairy products demand exact temperature control throughout their journey to market. Reefer containers maintain these sensitive products at 4°C (39°F) or below, preventing spoilage while preserving taste and nutritional value.

Temperature fluctuations pose significant risks to dairy quality, necessitating careful monitoring at every supply chain stage. Manufacturers often use specialized packaging materials that absorb moisture and limit oxygen exposure, further extending shelf life. The effectiveness of cold chain logistics directly impacts dairy producers' ability to compete in global markets.

Life-Saving Cargo: Pharmaceutical Transportation

Modern medicine increasingly relies on reefer container technology. Vaccines, biologics, and other temperature-sensitive pharmaceuticals require strict climate control during transport. Even minor temperature deviations can render these critical products ineffective, potentially endangering patient health.

Most vaccines require temperatures between 2°C and 8°C (36-46°F), necessitating precise monitoring throughout the supply chain. Pharmaceutical companies now deploy sophisticated tracking systems that provide real-time temperature and humidity data, with alerts for any anomalies. These technological safeguards help ensure medication efficacy from manufacturing facilities to end users.

Beyond Food and Medicine: Unexpected Reefer Applications

Reefer containers serve numerous specialized transportation needs beyond perishable food and pharmaceuticals. Chocolate, for instance, requires temperatures between 18°C and 20°C (64-68°F) to prevent melting and texture changes. Certain cosmetics and industrial chemicals also benefit from temperature-controlled transport to maintain product integrity.

Economic Impact: How Reefers Transform Global Trade

The widespread adoption of reefer technology has revolutionized international commerce. By enabling long-distance transport of perishable goods while maintaining quality, these containers have effectively eliminated traditional seasonal and geographic limitations for many products.

Efficient cold chain logistics create new market opportunities, allowing producers to expand their customer base globally. While this technology reduces food waste and improves resource utilization, its energy requirements and operational costs present ongoing challenges for the industry.

Conclusion

Refrigerated containers form the backbone of modern global supply chains, ensuring the safe transport of everything from fresh produce to life-saving medications. As international trade continues to expand, advancements in cold chain technology will play an increasingly vital role in economic development and sustainability. Behind every fresh meal and effective vaccine lies an intricate network of temperature-controlled logistics - a system that quietly but profoundly impacts our daily lives.