Reflow ovens have become an indispensable component in modern electronics manufacturing, particularly in surface mount technology (SMT) applications. These remarkable devices not only enhance production efficiency but also improve connection reliability in electronic products. Imagine thousands of tiny components being perfectly soldered on rapidly moving production lines — this is made possible by these sophisticated machines.

Understanding the Reflow Process

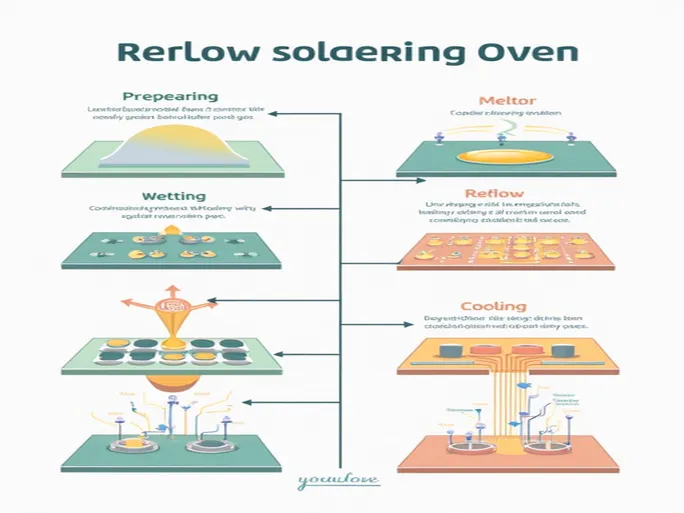

To appreciate their significance, it's crucial to understand how reflow ovens operate. The process consists of several key stages: preheating, soaking, reflow, and cooling.

The preheating stage gradually raises the temperature of both the circuit board and solder paste to prevent thermal shock damage. This phase typically occurs at relatively low temperatures, allowing solvents in the solder paste to evaporate and form a solid foundation for solder joints.

The Critical Soaking Phase

During the soaking stage, the solder paste begins to melt and penetrate the contact surfaces between the circuit board pads and surface-mounted components. This phase is particularly critical — proper solder wetting significantly enhances both the mechanical and electrical performance of solder joints. Temperature control here requires precise adjustment to ensure uniform penetration and optimal bonding with the substrate.

High-Temperature Reflow

The reflow stage follows, where the oven uses high-temperature hot air to completely melt the solder into a liquid state, enabling fusion with both the circuit board and components. Temperatures during this phase can reach 230°C to 260°C, varying according to different solder paste specifications. Insufficient temperature prevents proper melting, while excessive heat risks component damage or poor joint quality.

Controlled Cooling

The final cooling stage rapidly solidifies the solder, strengthening joint integrity. Cooling rate directly impacts solder quality — both excessively fast and slow cooling can create defects. Modern ovens address this with high-speed ventilation systems that ensure proper air circulation and temperature reduction.

Design and Functionality

Reflow oven design perfectly complements its function. A standard configuration includes multiple heating and cooling zones (typically 9 heating zones and 3 cooling zones) to maintain uniform temperature distribution across all 698 components during different processing stages. Each heating zone features independent temperature control, providing remarkable flexibility for diverse circuit board requirements.

Contemporary models often incorporate advanced temperature control systems and data logging capabilities. These technological enhancements not only boost production output but also guarantee consistent soldering quality. Real-time monitoring of temperature profiles and heating durations allows operators to promptly adjust parameters, ensuring every circuit board meets exacting standards. Some systems even feature intelligent management that automatically regulates zone temperatures, significantly reducing manual intervention.

Customs Classification Considerations

International trade of reflow ovens involves complex customs classification issues that directly impact tariff rates. These devices may fall under multiple Harmonized System codes, including:

- 8419.8990 (machinery for temperature treatment of materials)

- 8514.3000 (equipment for induction or dielectric loss heating)

- 8515.1900 (soldering equipment)

However, customs authorities typically classify reflow ovens under 8514.1090, as they create the heating environment for soldering rather than directly performing the welding action. The actual solder joint formation occurs through heating the solder paste rather than direct material heat conduction.

Behind these complex machines lies not just precision engineering and rigorous processes, but also thoughtful human-centered design that harmonizes operational simplicity with production efficiency. Even the most commonplace electronic products embody this fusion of technology and innovation. As manufacturing technology continues advancing, reflow ovens will undoubtedly play an increasingly vital role in driving electronics manufacturing forward.