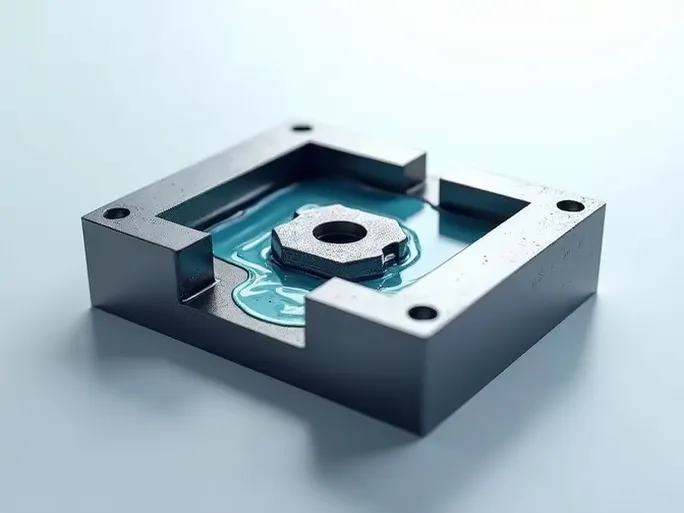

Imagine a world without release agents—precision metal die-cast components would struggle to separate cleanly from molds, drastically reducing production efficiency. These functional substances, which act as intermediaries between molds and finished products, play a pivotal role in modern manufacturing. However, due to their hazardous nature, shipping release agents by sea is far from straightforward. This article focuses on the maritime export requirements for release agents, particularly those classified as Class 9 hazardous materials, offering businesses a comprehensive compliance guide.

Release agents primarily reduce friction between mold surfaces and materials, preventing adhesion and ensuring product quality while enhancing production efficiency. They also facilitate easier demolding, minimize damage and deformation, and protect molds to maintain smooth concrete surfaces. Additionally, these agents must exhibit chemical resistance, thermal stability, and stress tolerance, resisting decomposition or wear. They should bond to molds without transferring to processed parts and must not interfere with painting or other secondary operations.

Industry experts highlight several critical considerations for shipping release agents by sea:

1. MSDS Documentation (English)

This is an essential document for booking shipments and must be provided at the time of reservation.

2. Dangerous Goods Packaging Certificate

This certificate verifies that the packaging meets hazardous material transportation standards. Businesses must obtain this document and ensure compliance with UN packaging regulations.

3. Booking Timeline

Reservations should be made at least 10 working days in advance to allow sufficient time for hazardous material declarations and warehouse arrangements.

4. Warehouse Cutoff Times

For less-than-container-load (LCL) shipments, goods must arrive at the warehouse before the cutoff deadline. Full-container-load (FCL) shipments must be delivered to the warehouse prior to the hazardous material declaration deadline.

5. Packaging Compliance

Strict adherence to UN-certified packaging standards is mandatory to ensure safe transportation.

Whether shipping via LCL or FCL, these requirements are non-negotiable. Businesses must comply with all regulations to guarantee the safe and lawful transport of release agents to their destinations. Neglecting any step could result in delays, confiscation, or other logistical complications.

In summary, exporting release agents by sea involves intricate hazardous material declarations and packaging standards. Companies must thoroughly understand applicable regulations, prepare all necessary documentation, and collaborate with specialized logistics partners to ensure smooth exports. Proactive planning and strict adherence to protocols are essential for mitigating risks and maintaining operational continuity.