In the world of logistics and international trade, ensuring the safety and compliance of shipped goods remains paramount. Among the various inspection methods, X-ray scanning has emerged as a crucial non-intrusive tool that helps customs authorities worldwide effectively evaluate import and export shipments.

The X-Ray Inspection Process

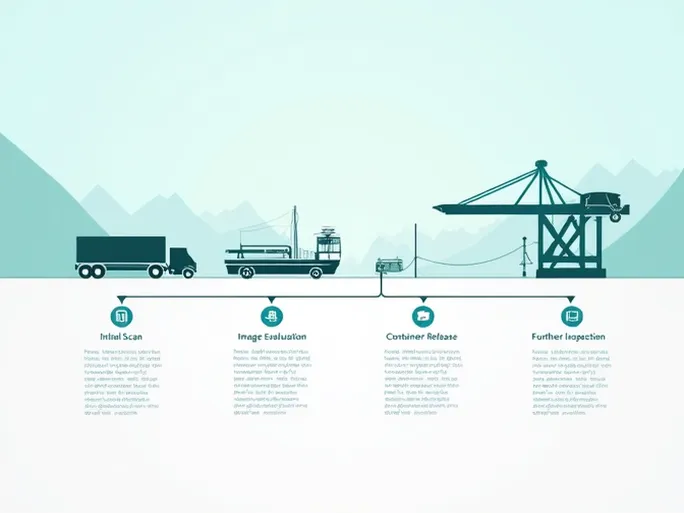

Commonly referred to as Non-Intrusive Inspection (NII) or Vehicle and Cargo Inspection System (VACIS), X-ray scanning is widely used for security assessments across various types of cargo. When U.S. Customs and Border Protection (CBP) selects a container for X-ray inspection, the shipment is transported to a marine terminal where specialized scanning equipment examines its contents.

This process offers significant advantages: it doesn't damage goods, eliminates the need for physical container openings, and substantially improves inspection efficiency while minimizing disruption to businesses.

Post-Scan Procedures and Timeframes

Following the scan, customs officers analyze the X-ray images to verify compliance and security. Containers with clear images that meet all regulations are typically released immediately. Those showing potential anomalies may require additional examination, potentially escalating to tailgate inspections or more thorough physical checks.

The entire X-ray inspection process usually takes between one to three days, though port congestion can extend this timeframe. During peak shipping seasons, when customs and port facilities face increased workloads, inspection capacity may become constrained. Industry professionals recommend that shippers account for potential delays when planning their logistics schedules.

Strategies for Smoother Clearance

Logistics experts emphasize that proper documentation and accurate declarations significantly reduce the likelihood of being selected for intensive inspections. Maintaining open communication with logistics partners allows for better trend analysis and risk assessment, helping identify potential compliance issues before they trigger customs inspections.

Many successful shipping operations implement proactive measures such as pre-shipment consultations with specialized logistics teams. These professionals can provide real-time updates about changing regulations and inspection protocols at different ports of entry.

As global trade continues to evolve, X-ray scanning stands out as an essential tool that balances security needs with operational efficiency. By understanding this process and preparing accordingly, businesses can navigate complex international shipping environments more effectively, gaining a competitive advantage in today's fast-paced trade landscape.