In today's globalized business environment, international container shipping serves as a vital hub connecting economic activities across nations, prized by enterprises for its efficiency and speed. Within this complex transportation system, communication between shippers and carriers is crucial, particularly when selecting the most suitable shipping methods. Recently, an innovative approach called "Non-Operating Reefer" (NOR) container usage has gained attention among industry professionals, showcasing the flexibility and innovation in modern container shipping practices.

I. Understanding Non-Operating Reefer Containers

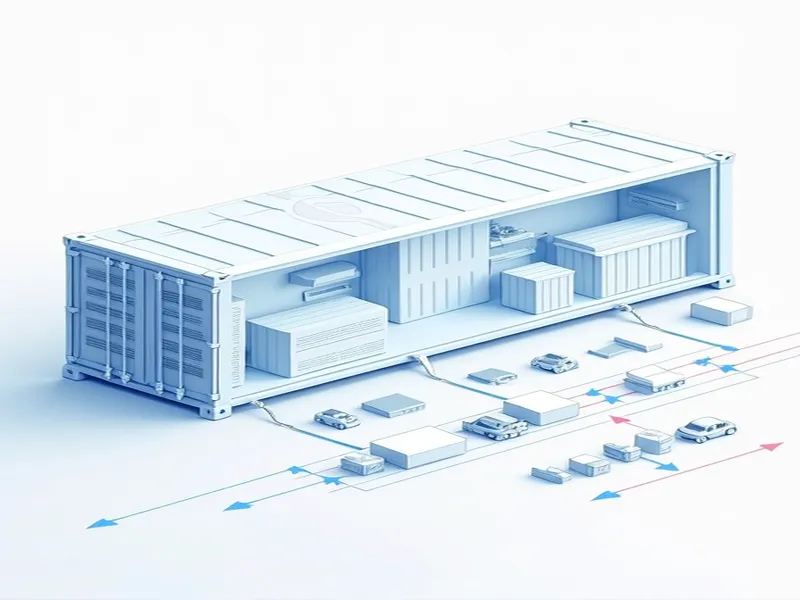

The "Non-Operating Reefer" concept refers to the innovative practice of using refrigerated containers (reefers) without activating their cooling function as regular dry containers. This approach not only demonstrates the flexibility of contemporary container shipping but also helps address container shortages. The full English name, Non-Operating Reefer Container, indicates these are refrigerated containers with their cooling systems turned off, typically used for transporting perishable goods like meat, fish, and dairy products.

Traditionally, reefer containers served as specialized tools for cold chain logistics. However, as market demands and container resource allocation evolve, shippers and carriers increasingly explore ways to utilize these containers more efficiently. For instance, a furniture manufacturer exporting goods from Tianjin to Riga opted for NOR containers when regular containers were unavailable. This decision, made in consultation with the client's designated freight forwarder, represented a carefully considered balance between transportation costs and efficiency.

II. Characteristics and Usage Specifications

NOR containers stand 9.5 feet tall—equivalent to standard 40-foot high cube containers (40HQ)—though their internal volume is slightly smaller than regular dry containers, requiring careful cargo selection and arrangement. Their specialized refrigeration technology and structural design mandate strict usage guidelines. For example, they are unsuitable for goods sensitive to odors, such as certain clothing items or chemical products—a critical consideration in transportation planning.

NOR containers can significantly improve container utilization rates and reduce resource waste. This advantage proves particularly valuable during global container shortages and imbalanced supply-demand situations on specific shipping routes. Effective NOR container deployment can lower overall transportation costs while increasing scheduling flexibility, offering shippers a practical solution to container scarcity.

III. Market Demand's Impact on NOR Usage

Shipping companies must constantly adjust their forecasts and management of refrigerated versus dry cargo demand. The availability of NOR containers fluctuates with these market demands, particularly during seasons with pronounced demand variations. Summer typically sees increased demand for frozen goods, while other seasons may favor dry cargo transportation.

To optimize operational costs and resource efficiency, carriers dynamically adjust NOR container deployment strategies. When refrigerated cargo demand declines, surplus reefer containers often transition to dry cargo use. This practice reduces freight costs while providing shippers greater flexibility, especially during periods of low cold chain demand. The NOR model exemplifies the shipping industry's agility in adapting to market changes.

IV. Key Considerations for Shippers

Despite its advantages, NOR container usage requires careful evaluation. First, shippers must understand these containers' unique characteristics and cargo restrictions to avoid transportation risks. Second, cost comparisons with standard containers—including leasing fees, potential lighterage charges, and time costs—are essential for making informed decisions. Finally, shippers should clarify carriers' procedures for NOR container conversion to ensure timely, quality delivery. Effective shipper-carrier communication remains paramount throughout this process.

V. Future Development Trends

As international trade and logistics evolve, NOR containers will likely demonstrate significant growth potential. First, industry collaboration will intensify, enabling better market adaptation and resource efficiency through coordinated shipper-carrier strategies. Second, technological advancements will enhance NOR containers' smart capabilities, such as real-time cargo monitoring, improving efficiency and reducing risks while potentially introducing new operational models.

Environmental sustainability will also shape future transportation practices. Balancing economic benefits with reduced environmental impact presents a key challenge for NOR and similar models. Strategies like optimized cargo management, reduced empty container returns, and intelligent container allocation could significantly lower carbon emissions across the supply chain.

VI. Conclusion

The NOR container model opens new possibilities for shipper-carrier collaboration while presenting fresh challenges and opportunities for industry innovation. Looking ahead, stakeholders should continue exploring alternative transportation solutions beyond traditional methods to better adapt to evolving market demands, improve overall efficiency, and contribute to global economic exchange. As this model develops and matures, its role in international container shipping will likely expand, creating new applications and scenarios.