In an increasingly interconnected global economy, international freight transportation plays a pivotal role in supply chain management. The choice of transportation methods not only directly impacts cargo safety and delivery timelines but also significantly influences corporate cost control and profit margins. Among various transportation modes, trunk line transportation stands out as a critical component of Full Container Load (FCL) shipping. This article explores the importance of trunk line transportation, compares two primary unloading methods—live unloading and drop-off unloading—and examines associated costs and strategic considerations for businesses.

What Is Trunk Line Transportation?

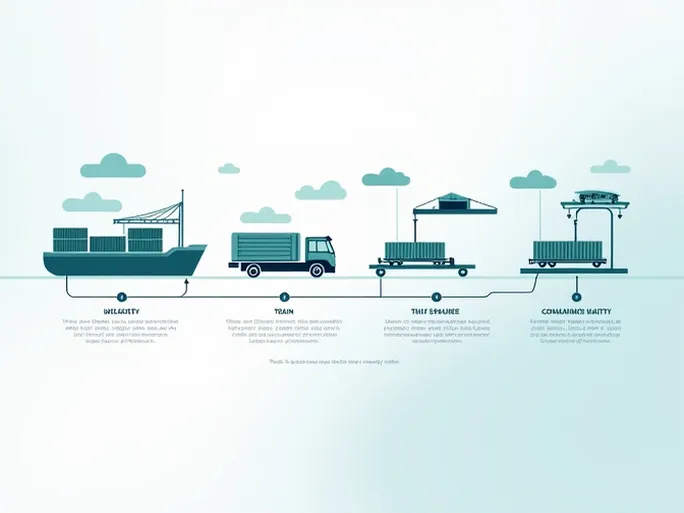

Trunk line transportation refers to the process of moving containerized cargo from ports to destination warehouses. Essentially, it bridges the gap between ports and end customers or storage facilities within domestic markets. The efficiency of this segment directly affects overall supply chain fluidity, making it indispensable in international logistics.

This process typically involves multimodal transportation solutions, including trucks and railways, to ensure timely and secure deliveries. Key characteristics include:

- Efficiency: Significantly reduces transit times and enhances supply chain responsiveness.

- Safety: Professional transport teams and management protocols ensure cargo integrity.

- Flexibility: Adaptable to diverse cargo types and distribution requirements.

Cost Structure of Trunk Line Transportation

Understanding cost components enables businesses to optimize budgets and make informed decisions. Primary expenses include:

1. Base Transportation Fees

The largest cost component, covering fuel, driver wages, and vehicle depreciation. Rates vary based on market competition, distance, and cargo specifications.

2. Waiting Time Fees

Incurred when unloading exceeds the driver's complimentary waiting period (typically 1-2 hours). Proactive warehouse coordination can mitigate these charges.

3. Drop-off Fees

Applied when containers remain at warehouses for extended unloading. Costs are generally fixed but subject to regional variations.

4. Chassis Usage Fees

Associated with trailer rentals, dependent on duration, location, and carrier policies.

Unloading Methods: A Comparative Analysis

Live Unloading

Drivers remain onsite until cargo is fully unloaded. Advantages include:

- Cost Savings: Avoids fees if completed within free waiting periods.

- Operational Efficiency: Ideal for warehouses with forklifts or automated systems.

Challenges: Potential delays may trigger additional costs and require streamlined warehouse workflows.

Drop-off Unloading

Containers are temporarily deposited at warehouses for later unloading. Benefits include:

- Flexibility: Accommodates labor shortages or high-volume periods.

- Time Management: Suitable for complex unloading processes (e.g., loose cartons).

Trade-off: Incurs standardized drop-off fees.

Strategies for Enhanced Efficiency

- Optimize Unloading Schedules: Align warehouse staffing and equipment availability with delivery timelines.

- Streamline Processes: Pre-verify cargo quantities and palletization details to accelerate unloading.

- Mode Selection: Balance cost and speed when choosing between live/drop-off unloading.

- Transparent Costing: Request detailed quotes encompassing all potential fees during procurement.

Conclusion

As global logistics competition intensifies, trunk line transportation emerges as a strategic differentiator. Informed decisions about unloading methods and cost structures directly impact cargo security, delivery performance, and corporate profitability. By mastering these operational nuances, businesses can refine supply chain agility, elevate customer satisfaction, and secure sustainable competitive advantages in international markets.