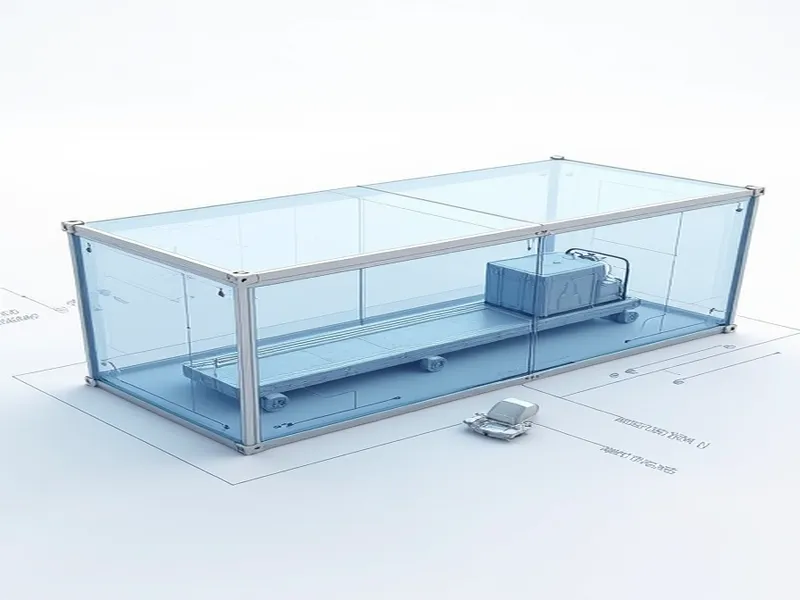

Air cargo containers, an essential component of modern aviation logistics, are specially designed to accommodate the unique shape and loading requirements of aircraft holds. Compared to traditional international standard shipping containers, they feature distinct structural designs and material selections aimed at maximizing cargo capacity and improving transportation efficiency. Today's air cargo containers not only boast more flexible forms and lighter materials but have also undergone numerous safety and convenience optimizations to adapt to the high-speed demands of air transport.

Material Innovation and Lightweight Design

The primary material used in air cargo containers is aluminum alloy, valued for its combination of lightness and strength. This choice reduces container weight, thereby increasing aircraft payload capacity and decreasing fuel consumption—factors that positively impact overall operational costs. While maintaining necessary strength and rigidity, container designs emphasize weight reduction, adhering to strict industry standards and aviation regulations to ensure both safety and functionality.

Interior Engineering for Cargo Stability

The interior design of these containers focuses on maximizing cargo stability and preventing movement during transit. This dual approach safeguards both the goods being transported and prevents damage caused by shifting loads. Consequently, restraint systems have become critical design elements, undergoing rigorous testing to ensure they maintain cargo positioning under various conditions.

Pressure Adaptation and Safety Features

In aviation transport, rapid cabin depressurization can instantly create safety hazards. Air cargo containers must therefore incorporate flexible internal pressure designs with adequate ventilation to accommodate cabin pressure changes. This maintains environmental stability within the container and minimizes potential pressure-related damage to goods—enhancing both container adaptability and reliability in extreme conditions.

Surface Design and Load Management

Both exterior and interior surfaces are engineered to be smooth, eliminating sharp edges or rough areas that might cause friction and damage during transport. Containers equipped with forklift slots require particularly meticulous design in their entry points and support bases, ensuring proper load transfer to the lower structure during handling operations. All designs and material selections undergo strict review and testing to comply with international standards, particularly the requirement that lower structures withstand no more than 9.55 kilopascals of pressure.

Ergonomic Handling Considerations

Container mobility features include strategically placed, ergonomic handles designed to withstand substantial force—typically no less than 4,449 newtons per handle. These thoughtful details enhance operational efficiency, particularly for ground crews who frequently move containers, significantly reducing physical strain while improving workflow.

Specialized Container Types

Current air cargo operations primarily utilize four container types:

- AKE: Designed for narrow-body aircraft

- AMF: Optimized for medium-range operations

- AAU: Built for maximum volume efficiency

- AMA: Specialized for heavy cargo

Each type serves specific purposes and operational scenarios, allowing logistics providers to select optimal containers for different cargo requirements. The design and manufacturing of air cargo containers represent a successful marriage of technology and practicality, playing a vital role in enhancing overall air freight efficiency.