In today's increasingly competitive business landscape, companies face the dual challenge of maintaining product quality while ensuring rapid delivery to meet consumer demands. The solution lies in improving supply chain execution efficiency—a critical factor that impacts not just production and delivery processes but overall operational success.

Defining Supply Chain Execution Efficiency and Its Significance

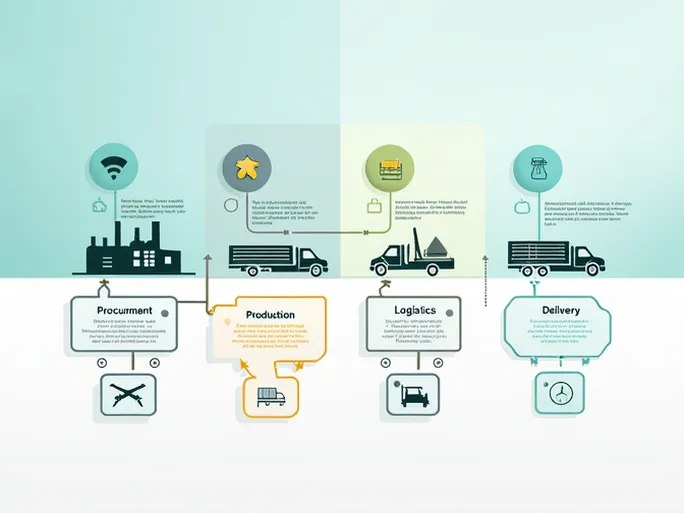

Supply chain execution efficiency refers to an organization's ability to optimize and streamline the entire product journey—from raw material procurement to final delivery. This concept emphasizes not just individual process efficiency but the coordinated performance across all supply chain components, including procurement, production, logistics, and warehousing. Its importance manifests in several key areas:

- On-time delivery: Ensuring timely product arrival builds customer trust and satisfaction.

- Cost management: Efficient execution reduces production and inventory expenses, expanding profit margins.

- Inventory optimization: Strategic inventory control minimizes capital tie-up and overstock risks.

- Information transparency: Real-time monitoring enables better strategic adjustments and operational improvements.

- Risk mitigation: Agile supply chains better withstand market fluctuations and disruptions.

Factors Influencing Supply Chain Execution Efficiency

Both external environmental factors and internal management practices affect supply chain performance:

External Factors

- Market demand volatility: Unpredictable shifts can create inventory imbalances.

- Global supply chain risks: Geopolitical tensions and natural disasters disrupt operations.

- Regulatory changes: Regional policy variations impact operational costs and efficiency.

Internal Management Factors

- Supply chain architecture: Well-designed networks shorten production cycles.

- Cross-functional collaboration: Effective interdepartmental communication enables better decision-making.

- Talent management: Skilled personnel enhance operational effectiveness.

- Technology infrastructure: Advanced systems support digital transformation initiatives.

Strategies for Improving Supply Chain Execution

Organizations can enhance efficiency through these key approaches:

Logistics & Transportation Management

- Route optimization: Implement intelligent routing systems to minimize transit time and costs.

- Inventory cost reduction: Refine demand matching and storage management.

Inventory Control

- Demand forecasting: Leverage data models to analyze historical sales patterns.

- Stock balancing: Proactively adjust inventory to prevent shortages or surpluses.

Technology Implementation

- Digital transformation: Adopt cloud computing and IoT for real-time data sharing.

- Advanced analytics: Utilize big data to identify and address supply chain weaknesses.

Partner Relationship Management

- Supplier collaboration: Establish information-sharing protocols for better coordination.

- Vendor assessment: Regularly evaluate partners to ensure supply chain stability.

Optimization Techniques and Future Outlook

In our rapidly evolving marketplace, businesses must employ progressive strategies to maintain competitive supply chains:

- Emerging technologies: Implement AI and IoT for enhanced monitoring and decision support.

- Lean methodologies: Eliminate process waste to reduce unnecessary expenditures.

- Predictive modeling: Develop robust forecasting tools using historical data.

- Collaborative ecosystems: Foster information flow and trust across supply networks.

As globalization increases supply chain complexity and unpredictability, organizations must balance efficiency with resilience. Market volatility, material cost fluctuations, transportation expenses, and pandemic-related disruptions all test supply chain durability. Thus, developing adaptable, responsive operations becomes imperative for business leaders.

Digital Transformation's Role in Supply Chain Efficiency

Digital adoption has become a cornerstone for modern supply chain optimization. Technologies like big data analytics, cloud platforms, and artificial intelligence enable:

- End-to-end visibility: Comprehensive tracking of logistics and inventory status.

- Data-driven decisions: Market trend analysis reduces human judgment errors.

- Seamless collaboration: Digital platforms break down information barriers.

- Operational agility: Rapid response mechanisms address unexpected disruptions.

Sustainability in Supply Chain Management

Environmental responsibility now plays a vital role in supply chain strategy:

- Eco-conscious procurement: Prioritize renewable materials and ethical suppliers.

- Waste reduction: Optimize processes to minimize resource consumption.

- Product lifecycle management: Incorporate sustainability from design to disposal.

- Brand enhancement: Sustainable practices improve corporate reputation.

Conclusion

In an era where supply chain efficiency increasingly determines competitive advantage, organizations must balance optimization with adaptability. Whether through digital transformation for enhanced visibility or sustainability initiatives for responsible operations, businesses that cultivate resilient, efficient supply networks will thrive amidst market uncertainties. The future belongs to organizations that can simultaneously maximize efficiency while maintaining flexibility to navigate an ever-changing global landscape.