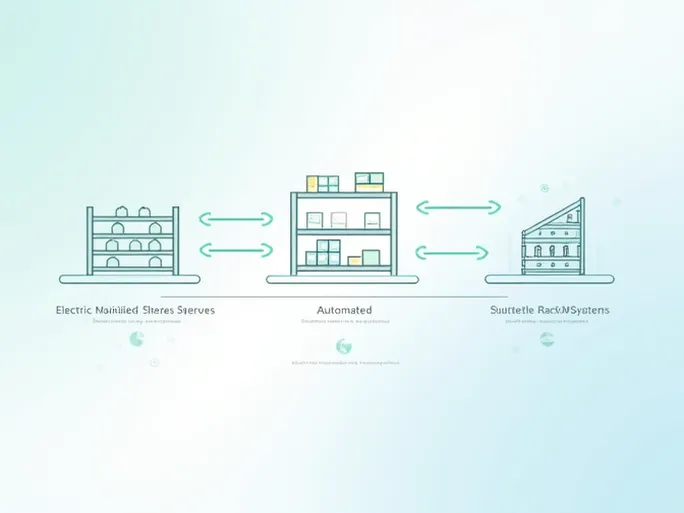

In today's increasingly competitive market environment, effective warehouse management has become crucial for businesses. The challenges of managing inventory more efficiently, reducing operational costs, and improving service quality are critical hurdles every company must overcome in its pursuit of profitability. To address these challenges, selecting the appropriate powered shelving solution is particularly important. This article will explore different types of powered shelving systems and demonstrate how intelligent warehouse solutions can enhance storage efficiency.

1. Electric Mobile Shelving: Flexible and Efficient Storage Options

Electric mobile shelving systems combine flexibility with high efficiency in warehouse storage. These systems operate by using electric drive mechanisms to move shelving units between fixed and mobile positions, allowing users to adjust shelf configurations according to actual needs and maximize every inch of available space. These systems come in two main types: light/medium-duty and heavy-duty mobile shelving, each suited for different warehouse scales and requirements.

Light/Medium-Duty Mobile Shelving

Also known as compact shelving systems, these electric mobile units are designed to increase storage density through tightly arranged shelving configurations. Typically not exceeding 12 meters in height, they are suitable for various warehouse environments.

-

Advantages:

- High space utilization: Achieves over 70% space utilization, significantly improving storage capacity compared to traditional shelving.

- Simple operation: Electric drive mechanisms dramatically reduce labor requirements while improving operational efficiency. Staff can complete storage and retrieval tasks with simple button controls.

-

Disadvantages:

- Lower access frequency: While excellent for space optimization, these systems are better suited for items with lower turnover rates and may not be ideal for fast-moving industries.

- Longer access times: The compact layout results in relatively longer access times that might impact overall warehouse efficiency.

Heavy-Duty Electric Mobile Shelving

For businesses handling heavy goods, heavy-duty electric mobile shelving provides an ideal solution with its robust construction and high load-bearing capacity.

-

Advantages:

- Exceptional load capacity: Designed to support heavier items while ensuring safe storage.

- Flexible configuration: Can be customized to meet various operational requirements.

2. Automated Storage and Retrieval Systems (AS/RS): The New Benchmark for Efficiency

With continuous technological advancements, automated storage and retrieval systems have emerged as the new standard in modern warehouse management. These systems combine computer management systems, automated handling equipment, and high-rise shelving to create highly efficient vertical storage solutions. Core components include shelving units, aisle stacker cranes, work platforms, scheduling control systems, and management software.

Advantages of AS/RS

- High-speed access: Modern technology enables significantly faster storage and retrieval operations, dramatically reducing goods turnover time.

- Maximum space utilization: Vertical space utilization can exceed 90%, generating substantial cost savings.

- Reduced labor costs: Automated processes minimize staffing requirements while decreasing human error.

- Enhanced safety: Fully automated operation improves protection for both personnel and goods.

Return on Investment Analysis

While AS/RS requires significant initial investment, the improved efficiency, reduced operational costs, and maximized space utilization deliver excellent long-term ROI. Many companies report substantial reductions in loss rates, improved customer satisfaction, and enhanced market competitiveness after implementation.

3. Shuttle Shelving Systems: The Perfect Balance of Flexibility and Density

Shuttle shelving systems combine shuttle carts, shelving units, battery-powered vehicles, and forklifts to create highly efficient pallet storage solutions. These systems are gaining popularity in modern logistics, particularly for businesses requiring high-density storage.

Components of Shuttle Shelving Systems

The system operates with shuttle carts moving along tracks to access goods, while forklifts handle loading and unloading, creating a highly efficient workflow.

-

Advantages:

- High-speed operation: Shuttle carts can complete storage and retrieval tasks in minimal time, optimizing efficiency.

- FIFO and LIFO functionality: Offers both first-in-first-out and last-in-first-out options for flexible inventory management.

-

Disadvantages:

- Moderate space utilization: Design limitations from forklift height and track systems prevent maximum space optimization.

Conclusion

When selecting powered shelving solutions, businesses must carefully consider their specific storage needs, product types, and budget constraints. Electric mobile shelving works best for low-turnover items, AS/RS introduces revolutionary efficiency concepts, while shuttle systems offer the ideal combination of speed and flexibility for dynamic operations.

In today's rapidly evolving technological landscape, companies must continuously improve their warehouse management capabilities to adapt to changing market conditions and maintain competitive advantage. Investing in the right powered shelving system represents not just a technological upgrade, but a strategic move to enhance overall operational efficiency and market position. As smart technology continues to advance, increasingly sophisticated warehouse solutions will emerge, helping businesses achieve safer, more efficient logistics operations. Choosing the right powered shelving system can transform warehouse management and secure a company's position in today's competitive marketplace.