In the vast field of international trade, screws serve as essential fasteners whose applications span across product assembly and fixation, making them indispensable in cross-border commodity transactions. Based on their characteristics, materials, and uses, screws are categorized under relevant headings in the Harmonized System (HS) of commodity classification. Specifically, steel screws primarily fall under HS heading 73.18. This article provides a detailed classification analysis of steel screws under this heading to help industry professionals better understand the categorization rules and their practical applications.

Defining Screws in the HS Context

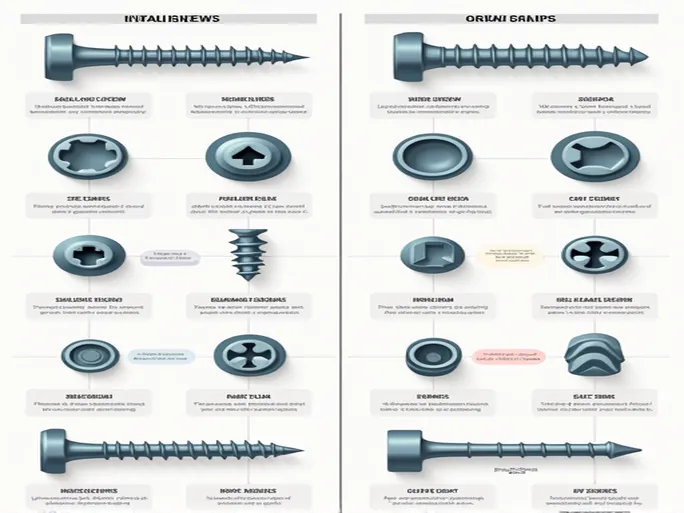

Before classifying steel screws, it's crucial to establish a clear definition. Known as "screws" in English, these fasteners are characterized by their threaded design and typically longer shanks that effectively penetrate and join different materials. Similar fasteners like nails and bolts have distinct differences: nails lack threading and rely on their heads for fixation, while bolts are generally used with nuts and have specific functional and morphological characteristics. Therefore, steel screw classification in the HS system must not be confused with other fastener types.

Detailed HS Classification of Steel Screws

The HS classification of steel screws follows internationally recognized standards and includes several specific categories:

- 73181100.00 - Coach screws (square-headed screws): All steel screws with square heads fall under this code. Their unique head design provides enhanced fixation for specific applications, particularly in joining wood and other materials.

- 73181200.01 - Wood screws (excluding those for civil aircraft maintenance and repair): Designed specifically for wood joining and fixation, these screws feature specialized threading that effectively grips wood fibers. They find widespread use in furniture manufacturing, wood product assembly, and construction.

- 73181200.90 - Other wood screws: This subcategory may include wood screws used in civil aircraft maintenance and repair, requiring careful interpretation in practical applications.

- 73181300.00 - Hook-headed and ring-headed screws: Characterized by their distinctive head designs that facilitate connection with other equipment or structures, these screws serve multiple industries.

- 73181400.01 - Self-tapping screws (excluding those for civil aircraft maintenance and repair): Capable of drilling their own holes in various materials, these screws offer efficient fastening solutions.

- 73181400.90 - Other self-tapping screws: Includes self-tapping screws potentially related to civil aircraft maintenance and repair.

High-Strength Screw Classification

The classification of high-strength screws includes:

- 73181510.01 - Other screws and bolts with tensile strength ≥800 MPa and shank diameter >6mm: These high-strength fasteners play critical roles in industrial applications, particularly in heavy-load bearing and automated equipment connections.

- 73181510.90 - Screws and bolts with tensile strength ≥800 MPa but shank diameter ≤6mm: This distinction helps select appropriate fasteners for different structural and load conditions.

- 73181590.01 - Other screws and bolts with shank diameter >6mm

- 73181590.90 - Other screws and bolts: This category encompasses screws meeting specific criteria while excluding those that fit the previously mentioned classifications.

Practical Implications for International Trade

The HS classification of steel screws involves multiple factors including head type, material, application, and strength. Understanding these categorization rules and logic proves essential for international trade professionals. To ensure smooth customs and trade processes, businesses must strictly adhere to relevant customs regulations and commodity classification standards while staying informed about policy updates and practical applications.

Ultimately, all classification requirements depend on the specific customs clearance requirements of individual countries. Industry professionals are advised to conduct thorough research and seek expert consultation before operations to guarantee full compliance with all regulatory processes.